|

|

|

|

|

|

|

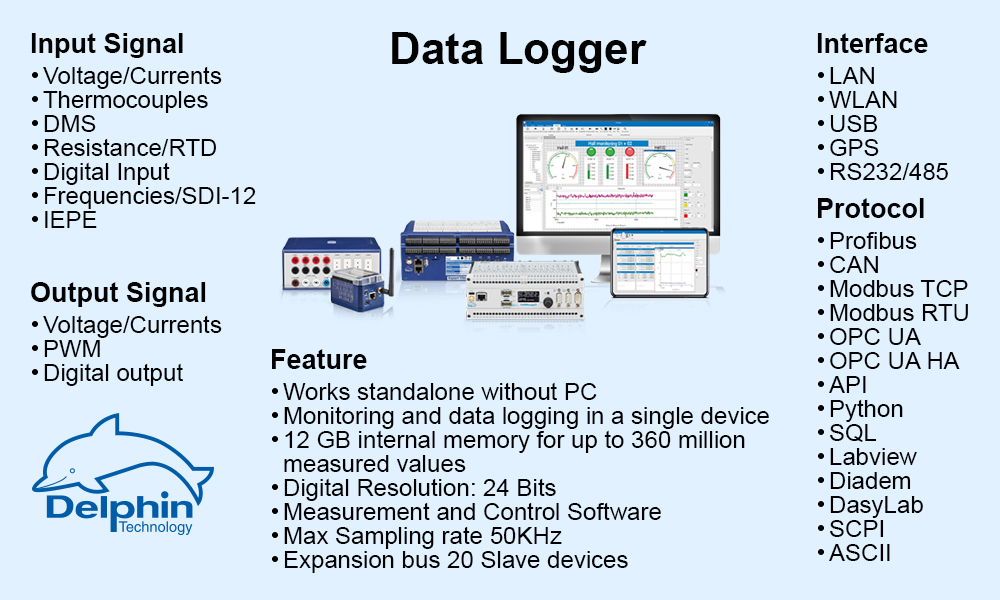

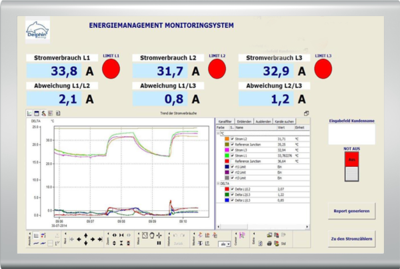

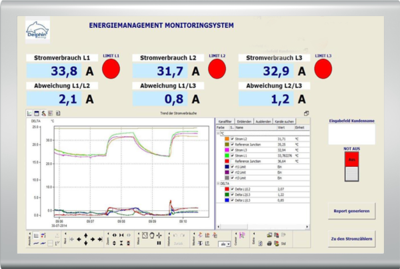

The EN50001 standard requires high energy consuming industries to implement energy saving measures and, when required, energy management systems. Energy consumption data therefore requires recording which can be performed using Message devices. Due to their LAN interfaces, these can be located throughout a company and installed directly at the plant and machinery. Consumption data can then be transmitted to a central data server or workstation PC. Universal inputs can directly measure analog units such as pressures and flows. Pulse inputs and/or serial interfaces can acquire data from electric, gas and water meters. Characteristic values for consumption data are processed and monitored directly within the devices. All the information can be analysed, portrayed and accounted for using the ProfiSignal software. |

|

|

|

Application features

-

Message devices represent a decentralised, intelligent point of collection for all energy data Message devices represent a decentralised, intelligent point of collection for all energy data

-

Problem-free connection of measuring meters for energy, quantities, gas, water and electricity, as well as measurement converter attachment Problem-free connection of measuring meters for energy, quantities, gas, water and electricity, as well as measurement converter attachment

-

Serial interfaces using ModBus RTU and ASCII protocols, and PROFIBUS DP Serial interfaces using ModBus RTU and ASCII protocols, and PROFIBUS DP

-

High sampling rates enable simultaneous fault analysis and process data acquisition High sampling rates enable simultaneous fault analysis and process data acquisition

-

Complete system including the ProfiSignal software for archiving, visualisation, analysis and protocols Complete system including the ProfiSignal software for archiving, visualisation, analysis and protocols

|

Practical example

A full system for energy data acquisition using Message devices has been used for some time by a well-known producer of print media. Decentralised Message devices are dispersed across the production site to acquire temperatures, pressures, flows and energy data. More than 1200 parameters are being recorded, processed, monitored and recorded using integrated software channels. More than 3,800 measurement values and their computed data are then transmitted via an existing network to a central server where they are recorded to a master database. The information on energy data acquisition can then be accessed from any workstation. In addition, process and fault analysis data can be accessed and evaluated at high resolution.

|

Typical areas of application

-

Energy and process data acquisition for printing machines Energy and process data acquisition for printing machines

-

Creation of output and load profiles Creation of output and load profiles

-

Monitoring of energy data and load detection Monitoring of energy data and load detection

-

Analysis of power parameters Analysis of power parameters

-

Measurements for energy efficiency according to EN 50001 Measurements for energy efficiency according to EN 50001

-

Energy data acquisition for refrigeration and cooling systems Energy data acquisition for refrigeration and cooling systems

-

Permanent energy data acquisition in steel and metal production Permanent energy data acquisition in steel and metal production

-

Process and energy monitoring in paper production Process and energy monitoring in paper production

-

Acquisition of energy data in a power plant Acquisition of energy data in a power plant

-

Bookkeeping for consumption data Bookkeeping for consumption data

|

|

|

|

|

|

Product & Technology News

N2930 Stainless B Series Panel PC

Application Selector

Download Catalogue

|