|

|

|

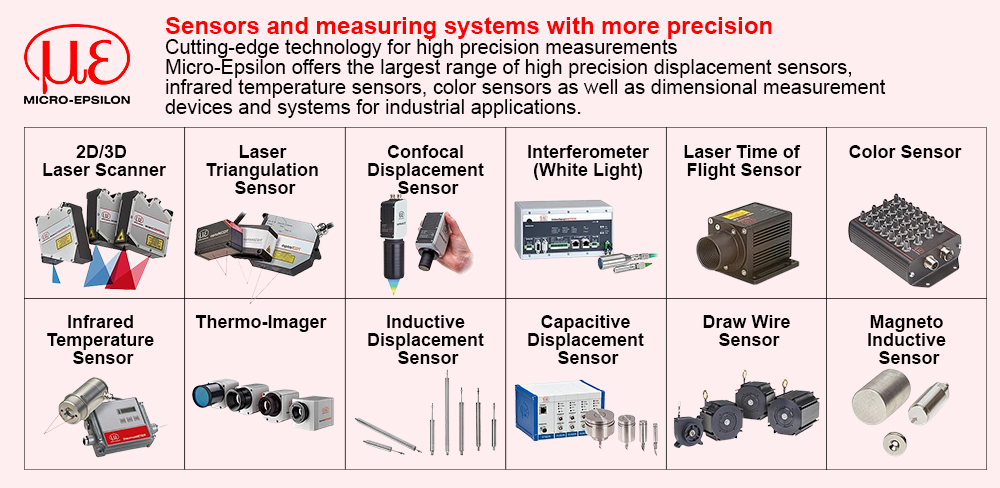

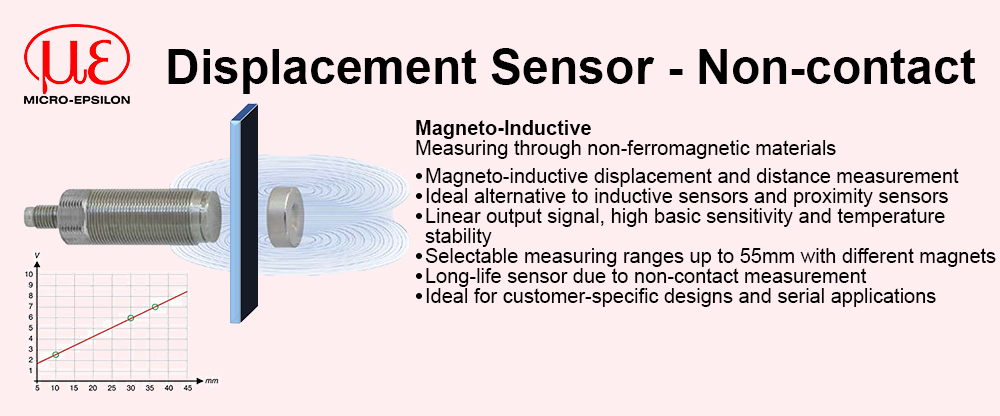

What is the measuring principle of magneto-inductive distance sensors?

|

|

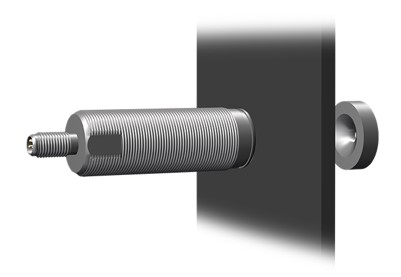

Magneto-inductive distance sensors (Patented Pending).

The mainSENSORis based on an innovative measuring principle developed by Micro-Epsilon in order to combine the advantages of both inductive and magnetic sensors.

|

|

|

|

|

|

|

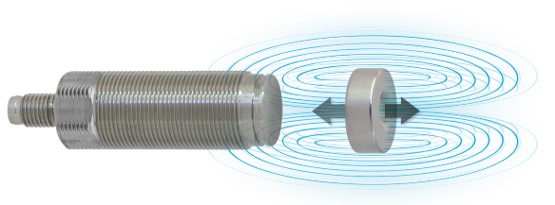

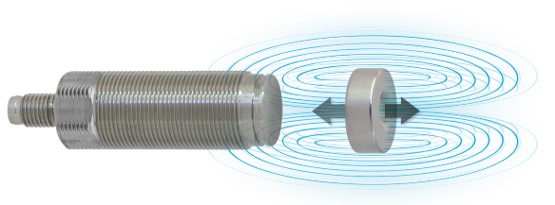

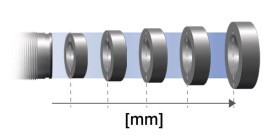

A magnet is fixed to the measurement object. The movement of the magnet induces a change in the magnetic flow in the sensor element, which is detected by the sensor coil. A linear relationship between output signal and magnet distance (self-linearization technology) is produced due to counteracting physical effects.

Different magnet with magnet strength are applied thus providing option of difference measuring ranges, up to 55 mm, these sensors are also used in special applications such as rotational speed measurement of, e.g., shafts and gear wheels.

|

|

|

Characteristics

|

-

Ideal alternative to inductive sensors and proximity sensors Ideal alternative to inductive sensors and proximity sensors

-

Linear output signal, high basic sensitivity and temperature stability Linear output signal, high basic sensitivity and temperature stability

-

Selectable measuring ranges up to 55mm with different magnets Selectable measuring ranges up to 55mm with different magnets

-

Long-life sensor due to non-contact measurement Long-life sensor due to non-contact measurement

-

Ideal for customer-specific designs and serial applications Ideal for customer-specific designs and serial applications

|

|

|

Advantages

|

|

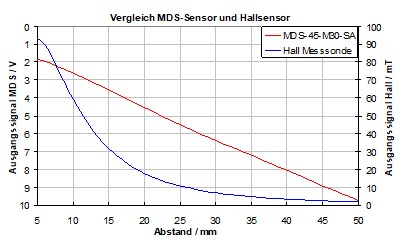

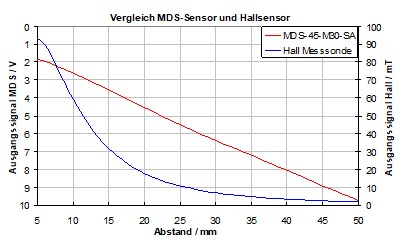

Linear relation between signal and magnet distance (self-linearization) despite large, frontal measuring range

Compared to Hall Effectsensors

Linear output signal Linear output signal

Increased frontal measuring range Increased frontal measuring range

Compared to inductive sensors

Significantly larger measuring range Significantly larger measuring range

Stable sensitivity at end of measuring range Stable sensitivity at end of measuring range

Compact sensor design (e.g. M12 with MR of 55 mm) Compact sensor design (e.g. M12 with MR of 55 mm)

|

|

|

|

|

|

Flexible sensor concept

|

|

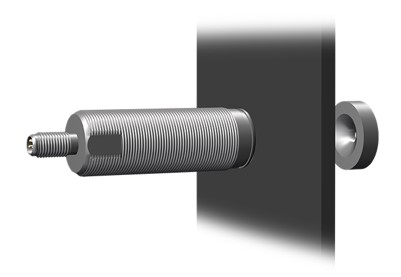

Due to their flexible concept, the sensors are ideal for a wide range of applications, particularly where big quantity and low priceare required. The standard sensors are designed in a stainless steel M12, M18 and M30 or a flat plastic housings suitable for industrial applications. Customer-specific modifications to the plate and sensor housing can be easily carried out for serial applications.

|

|

|

|

|

|

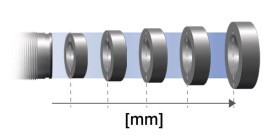

Defining the measuring range using magnets

|

|

With the magneto-inductive measuring principle, the magnets used act as target. To achieve difference measuring range, it is only necessary to change the magnet. Further calibration or sensor settings are superfluous. Therefore, measuring ranges of 20 to 55mm can be achieved using only one sensor.

|

|

|

|

|

|

Measurement through objects

|

|

Unlike conventional measuring methods, the magneto-inductive sensors enable measurements through non-ferromagnetic materials, particularly metals such as aluminum or stainless steel. A clear benefit is provided here as the sensor and the magnet can be installed separately in applications with closed systems or housings. It is therefore possible to mount the sensor safely in harsh environments.

|

|

|

|

|

|

|

|