|

||||||||||||||

What is the measuring principle of Thermal Imager?

|

||||||||||||||

|

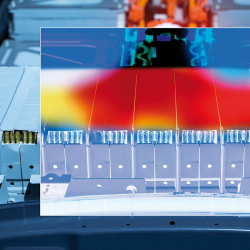

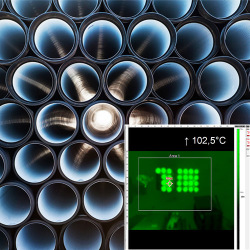

TIM thermal imaging cameras are designed for non-contact measurement of surface temperatures from -20 °C to 1900 °C. They enable efficient monitoring and control of temperature-critical processes both with low temperatures (e.g. in cooling chains) and with very high temperatures (e.g. in glass and metal processing). Their high thermal sensitivity makes these infrared cameras ideally suitable for precise and dynamic tasks. Different performance classes enable a suitable model to be selected for every application. The camera is connected via a USB interface, which also supplies the power.

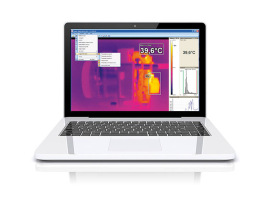

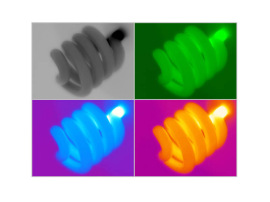

The thermoIMAGERTIM calculates the surface temperature based on the emitted infrared energy of objects. The two-dimensional detector (FPA - focal plain array) allows a measurement of an area and will be shown as thermographic image using standardized palettes. The radiometric processing of the picture data enables the user to do a comfortable detailed analysis with the software TIM Connect software. |

||||||||||||||

Characteristics |

||||||||||||||

|

||||||||||||||

Easy process integration |

||||||||||||||

|

||||||||||||||

Extremely lightweight, robust and compact |

||||||||||||||

|

||||||||||||||

License-free software |

||||||||||||||

|

||||||||||||||

Large temperature measuring range |

||||||||||||||

|

||||||||||||||

Applications |

||||||||||||||

|

||||||||||||||