|

|

|

Mobile machines & lifting technology

|

|

In lifting technology as well as in mobile machines, the monitoring of the movement or position is required for functional and safety aspects. Micro-Epsilon sensors are used in numerous measurement tasks to ensure a controlled sequence of movement. |

|

|

Reduced risk of tipping with loading wagons

|

|

In order to increase the safety of loading wagons, automatic braking systems are used. The brakes are activated if the lateral acceleration of a loading wagon becomes too high due to high speeds and tight curves and if the wagon threatens to tip over. The braking reduces the wagon’s speed and therefore both the lateral acceleration and the risk of tipping over. For electronic braking systems, acceleration sensors from the ACC53 series from Micro-Epsilon are used, which reliably detect the accelerations of the loading wagon.

|

|

|

|

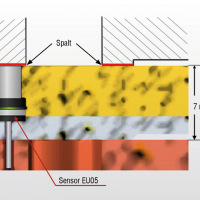

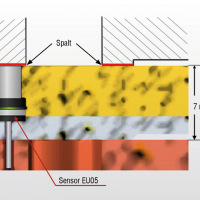

Gap analysis in axial piston pumps

|

|

So far, gap measurements inside the pumps were not possible because of the extreme requirements. The sensors must be resistant to high speeds, high pressures up to 1,000 bar and temperatures above 100 °C. Furthermore, the pumps are extremely compact, which significantly limits the space available for integration of sensors. Thanks to the extremely small sensor designs and their high pressure and temperature stability, the eddyNCDT inductive miniature sensors are ideal for this application. The eddyNCDT 3300 eddy current measuring system, which is one of the most powerful systems in the world, is therefore used on the test rig for evaluating the pumps.

eddyNCDT 3300 eddyNCDT 3300

|

|

|

|

Monitoring free-standing structures

|

|

High, free-standing structures such as cranes are monitored using inclination sensors which provide early warnings of a possible tip over in order to avoid accidents.

|

|

|

|

Wear measurement in the bearing

|

|

In modern marine diesel engines, the crankshaft bearing is subject to regular maintenance intervals. For predictive maintenance, inductive sensors (eddy current sensors) are used to permanently monitor the bearing wear. Despite harsh ambient conditions such as high temperatures, lubricants and pressures, the sensors measure the bearing movement reliably in long-term use.

Inductive sensors (eddy current) for displacement, distance & position Inductive sensors (eddy current) for displacement, distance & position

|

|

|

|

Piston position in the hydraulic cylinder

|

|

In modern hydraulic cylinders, the piston position is detected continuously. Therefore, inductive long-stroke sensors from Micro-Epsilon are used which are directly integrated in the hydraulic cylinder. Its robust design enables the sensor to provide stable measurement values despite pressure and oil.

induSENSOR EDS induSENSOR EDS

|

|

|

|

Position detection of the piston in the hydraulic cylinder

|

|

In order to detect the piston position of hydraulic cylinders, magnetostrictive and inductive sensors are directly integrated in the sensor. Therefore, the magneto-inductive sensor mainSENSOR is an alternative. The face-mounted magnet transfers its magnetic field to the piston rod. The sensor mounted outside then detects the magnetic field distribution along the rod and converts this into a linear output signal, which corresponds to the piston position.

Magneto-inductive distance sensors Magneto-inductive distance sensors

|

|

|

|

Collision detection in mowers

|

|

In agricultural machines, acceleration sensors monitor the mower in order to recognize collisions. When colliding with a stone, the mower will experience a movement that is detected by the acceleration sensors. When the mower is immediately switched off, damages can be reduced or avoided.

|

|

|

|

Jib lengths of mobile cranes

|

|

The current jib length is important when calculating the torque of the load on the crane. This length is measured with an integrated draw-wire sensor. This simple and telescopic measuring principle makes wire sensors predestined for the task. The sensors can also be retrofitted.

Draw-wire displacement sensors Draw-wire displacement sensors

|

|

|

|

Precision synchronized lifting system

|

|

Synchronized lifting systems enable the raising and lowering of heavy loads controlled for distance and force or the controlled forward feed of large components. To achieve this, eight or more cylinders are connected to a central high pressure hydraulic system (700 bar). The travel displacement of each individual cylinder must be measured as the actual value for the synchronized movement and supplied to the closed/open loop controller. Draw-wire displacement sensors of the wireSENSOR Series P60 are employed for this task.

WDS-P60 analog WDS-P60 analog

|

|

|

|

Displacement measurement on slag transporter

|

|

Draw-wire sensors are used to reduce the standstill time of slag transporters during the loading and unloading. They are installed on the tipping cylinder and the support cylinder. In this way, the signal of a limit switch no longer has to be waited for. Depending on the load state, the transporter can start the journey earlier. The sensor also withstands this demanding environment using a special case and wire extensions.

Draw-wire displacement sensors Draw-wire displacement sensors

|

|

|

|

Lift height of a catering vehicle

|

|

Catering vehicles play an important role in passenger air traffic. They are responsible for there being enough foodstuffs on board. It is especially difficult with the Airbus A380 to reach the loading hatch with the vehicle. Therefore, the load area of the scissor platform is also maneuverable. Draw-wire sensors are perfectly suitable for measuring this displacement.

Draw-wire displacement sensors Draw-wire displacement sensors

|

|

|

|

Rack control unit - lift height

|

|

The frequently used automatic rack control units make modern warehousing much easier. These units must automatically travel long distances and position the products with millimetre precision at the end. Modern optical laser sensors and also draw-wire sensors are used to monitor this movement. Draw-wire sensors are the more economical solution for distances up to 50 metres. Laser sensors which determine the distance using time of flight measurement are suitable for larger distances. Distances can be precisely measured and loads can be exactly positioned or delivered with their help.

Laser distance sensors for extra long ranges Laser distance sensors for extra long ranges

Draw-wire displacement sensors Draw-wire displacement sensors

|

|

|

|

Crane support distance

|

|

A truck-mounted crane is frequently the better solution in many cases where loads have to be lifted. As a mobile solution, safety also plays an important role here. Therefore a load torque limiter controls whether the crane can still lift or not. In order to ensure the maximum permitted load, the side crane supports must always be completely extended. If this would not be possible due to lack of space, the crane could not be put into operation. The dynamic process for measuring how far the crane supports have been extended facilitates a calculation of the permitted load capacity. Thus, the use of truck-mounted cranes can also be ensured where space is restricted..

Draw-wire displacement sensors Draw-wire displacement sensors

|

|

|

|

Lift platform – lift height

|

|

Side supports against tipping over are installed for lift trucks and lift work platforms. The crane or the platform can only be put into operation when the supports are completely extended so that there is also no danger of tipping in the case of long extension frames. However, sometimes this is not possible for spatial reasons. Therefore draw-wire sensors from Micro-Epsilon are used for measuring how far the supports are extended. A dynamic load torque limit across the actual support area is thus produced. Redundant measurement is performed as this is a safety relevant measured value.

Draw-wire displacement sensors Draw-wire displacement sensors

|

|

|

|

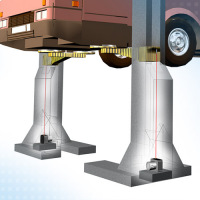

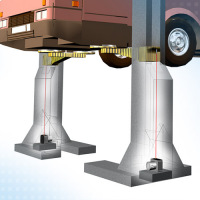

Synchronized lifting system lift height

|

|

Mobile lifting jacks are being used more and more often for commercial and railed vehicles. The lifting jacks for commercial vehicles are often designed as column lifts. In contrast, railed vehicles are often lifted on the frame. Any number of these lifting jacks can be combined into one system. As each lifting jack has its own drive for the lifting movement, the individual devices must be synchronized in order to ensure a completely level and oscillation-free movement. The lifting movement of each lifting jack is measured with a draw-wire sensor for this.

Draw-wire displacement sensors Draw-wire displacement sensors

|

|

|

|

Forklift lifting height

|

|

A large part of internal transportation is performed by forklifts. The risk of tipping the forklift when products are lifted is high. Therefore, the permitted speed has been restricted with limit switches. Draw-wire sensors from Micro-Epsilon measure the current lift height and make continuous speed regulation possible, depending on the height of the products.

Draw-wire displacement sensors Draw-wire displacement sensors

|

|

|

|

|

|