|

|

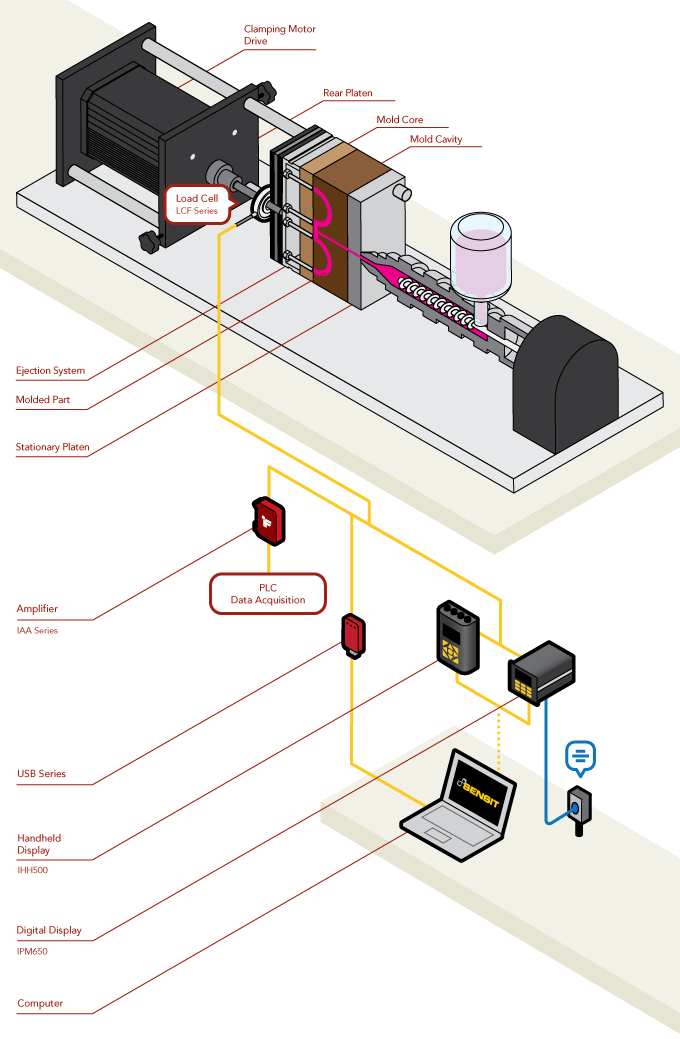

Application 159

Plastic Injection Molding Force Feedback

Application Summary

During plastic injection molding and die casting, the mold is clamped together to resist the rapid thermal expansion and contraction caused by the molten material filling the mold cavity. Flawed parts can be created if the mold is not kept properly clamped to resist thermal loading throughout the molding and casting process. To mitigate these thermal effects, Pancake Load Cells are placed at the clamp contact points, enabling machinery monitoring processes to adjust clamping forces.

Products in Use

FUTEK’s Universal Pancake Load Cells (LCF Series) coupled with the IAA Series Analog Amplifier for feedback into a PLC. |

|

|

How it Works

|