|

| |

SBL-2 Stainless Steel Shear Beam Load Cell

|

| |

|

|

| |

Description

The SBL-2 series of shear beam load cells have been specifically designed for use in a wide range of weighing applications, including vessel weighing, floor scales and pallet trucks. There are a number of mounting accessories available to make installation easier and to ensure that the best system accuracy is maintained. Please consult with LCM Systems engineers for further details, based on your application requirements.

The SBL-2 offers high accuracy and superior immunity to shock or side loading. Manufactured from stainless steel with high performance potting for superior environmental protection, the load cell provides long term reliability. There are two versions available; one with a full metric thread and another with a blind hole for load attachment.

The SBL-2 series can be supplied on its own or combined with our extensive range of instrumentation to provide a complete system.

|

| |

Features

250kgs to 2000kgs 250kgs to 2000kgs Stainless steel construction Stainless steel construction Environmentally sealed to IP67 Environmentally sealed to IP67

|

| |

Options

Vessel mounting assembly (using blind hole version of SBL-2) Vessel mounting assembly (using blind hole version of SBL-2) Shock mounting assembly Shock mounting assembly Platform foot mounting assembly (using blind hole version of SBL-2) Platform foot mounting assembly (using blind hole version of SBL-2)

|

| |

| |

|

| |

SHK-D D Type Cabled Load Shackle

|

| |

|

|

| |

Description

The LCM range of load shackles is designed for lifting and weighing in rugged or harsh environments.The shackle pins are manufactured to an exacting specification and are machined from high tensile stainless steel to 6.5te and forged from high tensile cabon steel from 9.5te. The basic shackle uses the Crosby G2150 series.

This range of load shackles is proof loaded to 150% of the normal rated load, and is available in a range from 1 tonne to 35 tonne. The SHK-D is internally gauged and the whole instrumented area is sealed to IP67 to protect it in service.

They are simple to install and are available in standard shackle sizes. As an option, a rotating bobbin can be supplied to centralise the load and to minimise any point-load effects when the load shackle is placed under load. We are also always happy to discuss any special requirements that can be accommodated.

The SHK-D load shackle series can be supplied on it's own or combined with our extensive range of instrumentation to provide a complete load monitoring system.

|

| |

Features

Cabled D type load shackle Cabled D type load shackle Can be supplied with integral signal conditioning Can be supplied with integral signal conditioning Environmentally sealed to IP67 Environmentally sealed to IP67 Many other options available Many other options available Optional load centralising bobbin Optional load centralising bobbin Ratings from 1 tonne to 35 tonnes Ratings from 1 tonne to 35 tonnes Shackle and load pin fully certified Shackle and load pin fully certified Simple installation and operation Simple installation and operation

|

| |

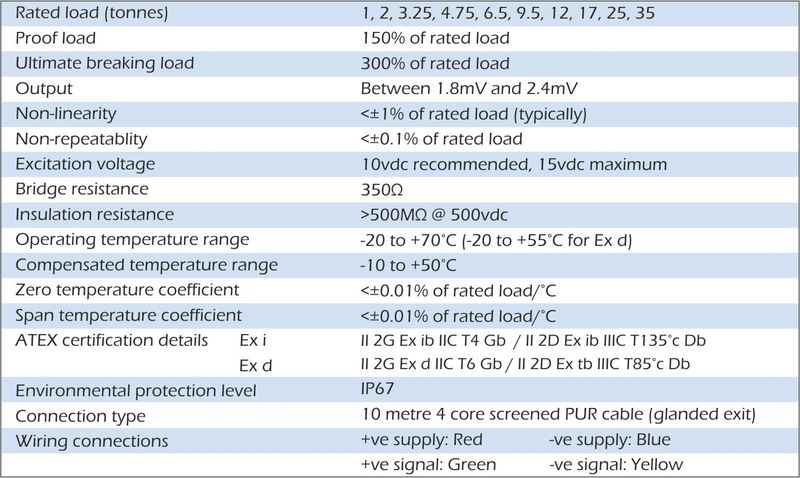

Specification

|

| |

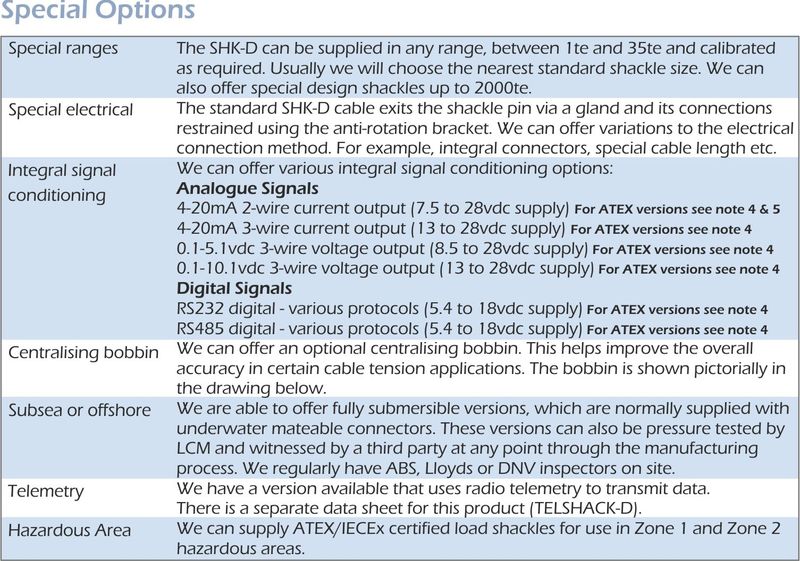

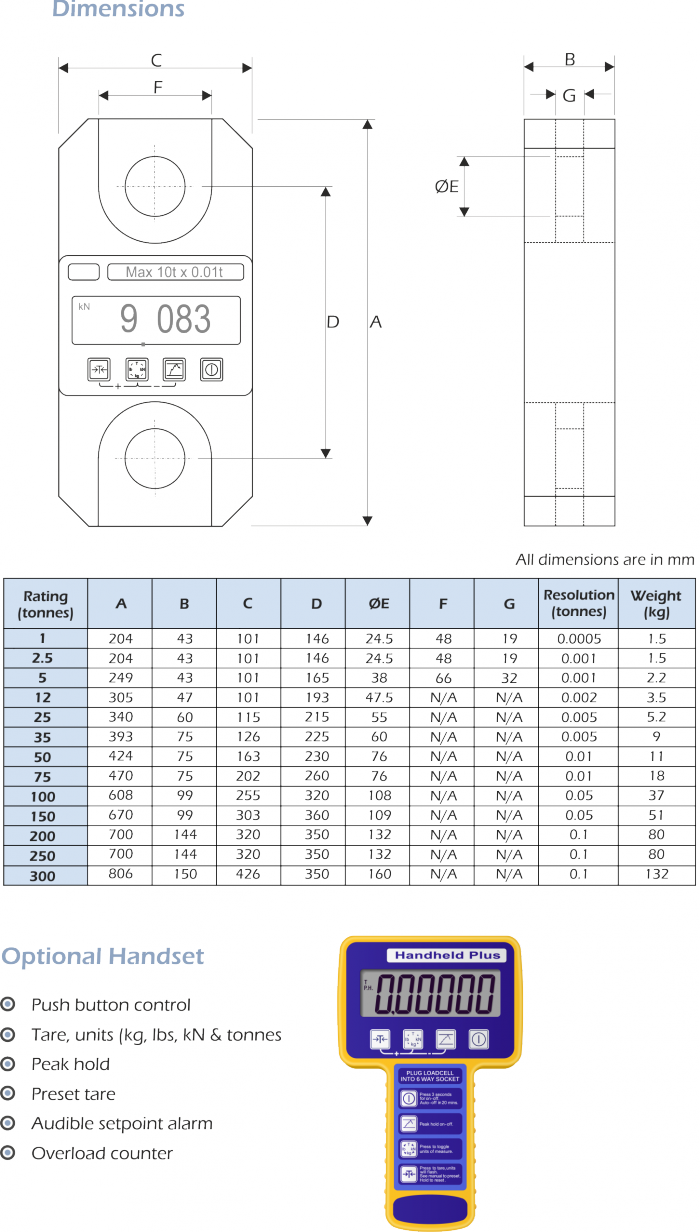

Dimensions

|

| |

Options

|

| |

Applications

Under-hook Hoist/Crane Weighing Under-hook Hoist/Crane Weighing Cable Tension Monitoring Cable Tension Monitoring Towing/Mooring Tension Towing/Mooring Tension Crane Safe Load Monitoring Crane Safe Load Monitoring

|

| |

| |

|

| |

SILL Self Indicating Link Load Cell

|

|

|

|

|

|

► Ranges 1 tonne to 300 tonne

► Lightweight Aluminium Construction

► Shackle holes are steel bushed

► Environmentally Sealed to IP65

► Audible alarm facility as standard

► Can display as standard in t, kg, lb & kN Selectable by operator

► Remote handheld facility available

► Peak Hold facility

► Can be supplied with various bespoke software packages

The LCM SILL series have been designed for lifting and weighing in rugged or harsh environments, being manufactured from high tensile aluminium to minimise weight (has steel bushes to provide added wear protection from shackles etc). The SILL series are simple to install and are matched to standard shackle sizes. The have a built in display which can be selected by the user to display the applied weight or force in t, kg, lb or kN. There is an in-built audible alarm, which can be set by the operator, to warn when an applied weight/force level is met.

For applications where the operator is unable to read the display, there is a handheld remote available. This remote replicates exactly, all the functionality that is available on the link itself. Other features that are available include Peak Hold, Gross/Net, Pre-set Tare entry. There is also a RS485 digital output available. LCM Systems can offer a software design facility to design bespoke software to meet any specific application requirements that may be required.

|

| Back to Top |

| |

|

| Rated Load (tonne) |

1, 2.5, 12, 25, 35, 50, 75, 100, 150, 200, 250, 300 |

| Proof Load |

200% of Rated Load |

| Safety Factor |

500% of Rated Load (1, 2.5, 12, 25, 35, 50, 75, 100, 150, 200 te)

400% of Rated Load (100, 150, 200, 300 te)

|

| Display |

6 digit LCD, 25mm high digits with unit indication |

| Display Units |

te, lbs, kg and kN |

| Non-Linearity |

< ±0.1% of Rated Load |

| Non-Repeatability |

< ±0.05% of Rated Load |

| Power Supply |

9V PP3 battery |

| Operating Temperature Range |

-10 to +50°C |

| Compensated Temperature Range |

-10 to +50°C |

| Zero Temperature Coefficient |

< ±0.02% of Rated Load/°C |

| Span Temperature Coefficient |

< ±0.02% of Rated Load/°C |

| Environmental Protection Level |

IP65 |

|

| Back to Top |

| |

|

|

| Back to Top |

| |

|

► Click here to download - SILL Datasheet

► Click here to download - SILL Instruction Manual |

| Back to Top |

|

► Under hook crane weighing

► Crane load testing

► Beam proof testing

► Water bag calibration

► Cable tension measurement |

| |

| |

|