|

|

DCELL In-Cell Digital Strain Gauge to Data Converter

|

|

|

|

|

|

► Simple mounting using M2 screw

► Connections via plated through holes

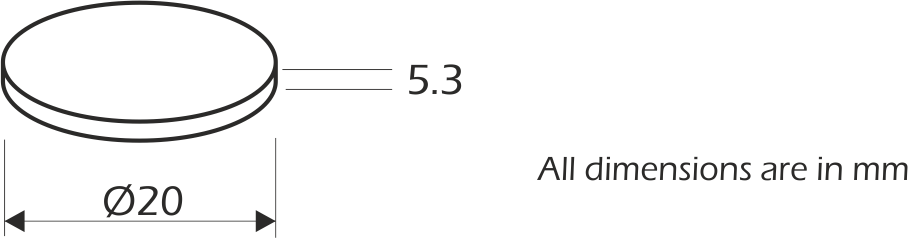

► Low profile to fit in very small apertures

► Baud rates to 230k

► High speed to 500 Readings/Sec

► ±15KV ESD protected

► Real mV/V calibration

► Noise Immunity 5x heavy industrial level

► Diagnostics LED

► Remote shunt calibration

► Very high stability

► Peak and trough recording

► Programmable dynamic filter

► Operating voltage (5.4 - 18Vdc)

The DCELL is a high performance digital signal conditioner for the precision measurement of strain gauge based transducers. The Micro Miniature PCB is designed to fit inside the majority of sensors, providing a 'digital' load cell with the benefit of very high stability and an RS485 output. LCM Systems offer the DCELL as a standalone product or built into most of our load cell based products. Including the DCELL into load cell based product enables the building of very high accuracy load cells, using the built in linearization and temperature compensation facilities. LCM Systems can also supply PC based software packages, specially written to interface with DCELL based load cells and pressure transducers. Please contact our technical department to discuss your requirements. For applications where it is not possible to fit the DCELL within the transducer, there is an in line housing available (Model ILE).

|

| Back to Top |

|

|

Product

|

DLCH High Stability

|

DLCS Industrial Stability

|

|

| Description |

Min |

Typ |

Max |

Min |

Typ |

Max |

Units |

| Bridge Excitation |

4.5 |

5 |

5.25 |

4.5 |

5 |

5.25 |

VDC |

| Bridge Impedance |

320 |

350 |

5000 |

320 |

350 |

5000 |

Ohms |

| Sensor Impedance (18v supply) |

320 |

350 |

5000 |

320 |

350 |

5000 |

Ohms ∆ |

| Sensor Impedance (12v supply) |

120 |

350 |

5000 |

120 |

350 |

5000 |

Ohms ∆ |

| Bridge Sensitivity |

-3 |

|

+3 |

-3 |

|

+3 |

mV/V |

| Offset Temperature Stability |

|

1 |

4 |

|

5 |

10 |

ppm/°C |

| Gain Temperature Stability |

|

3 |

5 |

|

30 |

50 |

ppm/°C |

| Offset Stability with time |

|

0.002 |

0.008 |

|

0.0035 |

0.016 |

%FR |

| Gain Stability with time |

|

|

30 |

|

|

300 |

ppm of FR/1st year |

| Non Linearity |

|

0.0005 |

0.0025 |

|

0.0005 |

0.0025 |

%FR |

| Internal Resolution |

|

16 Million |

|

|

16 Million |

|

Counts/Divisions |

| Resolution @ 1Hz (Noise Stable) |

|

400,000 |

|

|

100,000 |

|

Counts/Divisions |

| Resolution @ 10Hz (Noise Stable) |

|

120,000 |

|

|

40,000 |

|

Counts/Divisions |

| Resolution @ 100Hz (Noise Stable) |

|

50,000 |

|

|

10,000 |

|

Counts/ Divisions |

| Resolution @ 500Hz (Noise Stable) |

|

18,000 |

|

|

5,000 |

|

Counts/ Divisions |

|

Optional

|

| Temp Measurement Resolution |

0.1 |

0.1 |

°C |

| Temp Measurement Accuracy |

1 |

1 |

°C |

| Notes |

From original offset at any time Stability over 100 seconds Subject to supply voltage (see electrical specifications) |

|

Electrical

|

| |

Min |

Typ |

Max |

Min |

Typ |

Max |

Units |

| Power Supply Voltage |

5.4 |

12 |

18 |

5.4 |

12 |

18 |

Vdc |

| Power Supply Noise/Ripple |

|

|

100 |

|

|

100 |

mVac pk-pk |

| Supply Current (350R Bridge) |

|

45 |

60 |

|

45 |

60 |

mA |

| Power@10V Supply (350R Bridge) |

|

350 |

|

|

350 |

|

mW |

| Excitation System |

|

4 wire |

|

|

4 wire |

|

|

|

Communications

|

| |

Min |

Typ |

Max |

Min |

Typ |

Max |

Units |

| RS485 Data Rate |

2400 |

|

230k |

2400 |

|

230k |

Baud |

| Protocols |

ASCII, MANTRABUS II, Modbus RTU |

|

CE & Environmental

|

| Storage temperature |

-40 to +85ºC |

| Operating temperature |

-40 to +85°C |

| Relative humidity |

95% maximum non-condensing |

| Safety/Low Voltage Directive |

73/23/EEC amended by 93/68/EEC

BS EN 61010-1:2001, IEC 1010-1-1990 |

| EMC Directive |

89/336/EECBasic Standard

BS EN 61326:1998 |

| EMC Emissions |

BS EN 55011:1998 |

| EMC Immunity |

BS EN 61000-42:1995BS EN 61000-4-3:2002

BS EN 61000-4-3:2002

BS EN 61000-4-4:2004

BS EN 61000-4-11:2004 |

|

| Back to Top |

|

|

| Back to Top |

|

Click here to download - DCELL Datasheet

Click here to download - DCELL Instruction Manual |

|

| The DCELL offers a RS485 digital output (in various protocols). LCM Systems can offer the DCELL as part of a complete system, including sensors (and can be integrated into many sensors) and bespoke software, written specifically for your application. The software is usually developed using the Visuallink software platform. Contact LCM Systems to discuss your software/application requirements. |

|

► High accuracy Aircraft Weighing

► Crane weighing, using LDD-LITE large digit display

► Centre of Gravity PC based systems

► Condition and safety monitoring systems |

| |

| |

|