Foundry Scrubber Reservoir Ultrasonic Level Sensor_________________________________________________________________

When a Midwest foundry needed reliable level measurement of their scrubber reservoirs, they turned to Flowline. The firm manufactures metal castings and scrubbers are required to separate hazardous pollutants from their exhaust streams. The resulting highly acidic wastewater collects in sumps, where its measured, and periodically transferred for neutralization. Plant operators had problems with a different brand of ultrasonic level sensors, due to condensation build-up on the transducer, and its attenuating effects on acoustic signal transmission and receipt. For this reason, Flowline suggested the use of our reflective ultrasonic sensors that are unaffected by condensation. See why. The ultrasonic sensors provide continuous level data to the PLC, which in turn, monitors the sumps and controls the wastewater transfer. Flowline is reliable level measurement. |

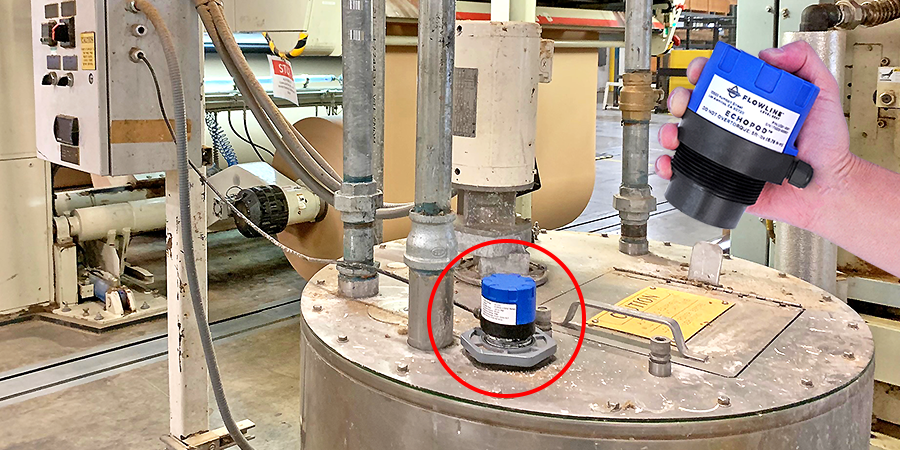

Resin Bulk Storage Tank Radar Level Sensor_________________________________________________________________

When a Midwest composite material manufacturer needed reliable level measurement and control of their resin storage tanks, they turned to Flowline. The company binds various materials with resin that they manufacture, heat and store onsite for daily production. Formaldehyde based resin is highly vaporous, especially when agitated during tank filling. At that time, operators experienced intermittent measurement from ultrasonic level sensors due to the attenuating effects of vapor on acoustic signals. They also wanted a high level shut-off for spill prevention. For these reasons, Flowline suggested the use of our radar sensors that are unaffected by vapor, and a Switch-Pak high level controller for pump shut off safety. The radar sensor provides continuous level data to the PLC, which in turn, monitors the storage tanks and controls the process. Flowline is reliable level measurement. |

Aluminum Sulfate Tank Ultrasonic Level Sensor_________________________________________________________________

When a Washington state municipality needed reliable level measurement of their aluminum sulfate tanks, they turned to Flowline. Aluminum sulfate is a highly acidic, hygroscopic compound that’s often used as a water treatment filter agent. The soluable crystals bind or clump with impurities, and increase filter efficiency. In high concentration, aluminum sulfate can have a pH value as low as 2. The operators experienced shortened level sensor life, and required a non-contact, corrosion resistant sensor. Additionally, the tanks are in a hazardous area due to methane, and they required intrinsic safety. For these reasons, Flowline suggested the use of our intrinsically safe ultrasonic sensors that are ideal for corrosive chemical feed applications. The ultrasonic sensors provide continuous level data to the SCADA, which monitors and controls the chemical feed process. Flowline is reliable level measurement. |

Restaurant Septic Tank Guided Wave Level Sensor_________________________________________________________________

When a Texas restaurant needed reliable level measurement of their septic tank, they turned to Flowline. Greywater, cooking oil, soap and grease enter the tank daily, and depending upon business volume and leach field efficiency, the tank requires pumping 1-3 times per month. Like most operators, they’re focused on customers, not septic tanks and back-ups were inevitable. When it came time for a new septic system, reliable tank measurement was at the top their list, and they wanted a level sensor that performs in coating liquids. For this reason, Flowline suggested the use of our guided wave sensor with rod antenna, that’s unaffected by material build-up on the sensor. The guided wave sensor provides continuous level data to the indicator-alarm. Flowline is reliable level measurement. |

Biosolids Truck Loading Silo Radar Level Sensor_________________________________________________________________

When an Arkansas water treatment plant needed reliable level measurement of their biosolids, they turned to Flowline. Sludge is dewatered, pulverized and transferred to a truck loading silo. There local farmers receive bulk loads of nutrient rich fertilizer for their fields. Powder or sand like, the silo’s very dusty, and the operators had negative experiences with other radar sensors that failed due to material build-up. For this reason, Flowline suggested the use of our radar sensors with high power parabolic antennas that are unaffected by build-up, and thus perfect for dusty silo applications. The radar sensor provides continuous level data to the SCADA, which monitors the silo and controls the biosolids process. Flowline is reliable level measurement. |

Tiger Exhibit Water Pool Ultrasonic Level Sensor_________________________________________________________________

When a Mississippi zoo needed reliable level measurement of their tiger exhibit pool, they turned to Flowline. Only 2500 Bengal tigers remain in the wild, and the zoo’s breeding program plays a key role in the species conservation. The veterinary team sites stress as the most critical factor in breeding success or failure, and nothing burns tiger stress faster than water play. But when 700 pound animals hit the pool, they can generate 3′ waves with lots of splashing. During which, the conductance level switches would chatter the fill valve, reducing the valves life and causing water hammer. The maintenance manager wanted a non-chattering reliable solution that could directly replace their existing level switch architecture. For this reason, Flowline suggested the use of our ultrasonic level sensors with embedded relays, control and dampening logic. The ultrasonic sensor provides dampened pool monitoring, and the relays were simply configured to the previous switch points. Flowline is reliable level measurement. |

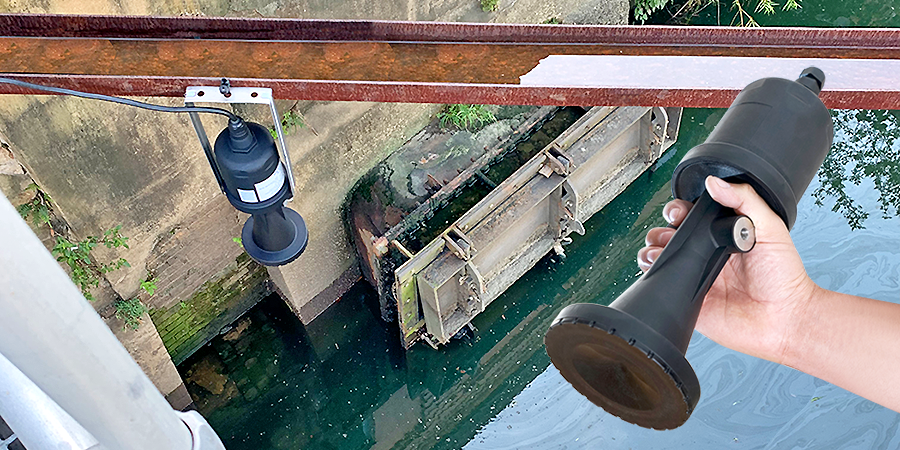

New Orleans Dike And Levee Radar Level Sensor_________________________________________________________________

When the city of New Orleans needed reliable level measurement of their dikes and levees, they turned to Flowline. Post Katrina, the city has made tremendous progress in bolstering its flood control infrastructure and technology. Level measurement plays a key role in this architecture, and hundreds of Flowline level sensors are deployed throughout their system. Recently, the city has shifted to radar sensors in these exposed outdoor applications because radar is unaffected by wind or rain. The encapsulated sensor is designed for suspended, bracket mounted installation over dams, rivers, canals or reservoirs, in all types of weather. The radar sensor provides continuous level data to the SCADA, which monitors the levees and controls the dikes. Flowline is reliable level measurement. |

Sodium Hydroxide Day Tank Ultrasonic Level Sensor_________________________________________________________________

When a Southeast paper manufacturer needed reliable level measurement of their caustic soda mixing tanks, they turned to Flowline. Sodium hydroxide is widely used to extract lignin, an organic polymer found in plant material, that makes the pulp too rigid for paper applications. NaOH is a highly corrosive and crystallizing media that’s difficult to measure. Numerous day tanks receive, periodically mix to maintain consistency, and dispense the chemical throughout the plant. Here the operators had ongoing level problems with float switches that would stick due to coating and chatter due to agitation. For this reason, Flowline suggested the use of our non-contact ultrasonic sensors installed in a stand-pipe. The ultrasonic sensors provide continuous level data to the PLC, which monitors the day tanks and controls the filling and mixing process. Flowline is reliable level measurement. |

Ammonia Bulk Storage Tank Radar Level Sensor_________________________________________________________________

When a Southeast biomass power plant needed reliable level measurement of their ammonia bulk storage tank, they turned to Flowline. The plant’s raw exhaust stream contains hazardous pollutants that are safely removed via their scrubber. Liquid ammonia is one of the chemicals injected into the scrubber as part of the process. Highly corrosive and vaporous, ammonia is difficult to measure. A large bullet tank supplies the scrubber with 19% ammonia. There, the operators had problems with a different radar level sensor brand, that would lock up on the stand-pipe fitting connections. For this reason, Flowline suggested the use of our radar sensors that have digital signal processing technology that disregards erroneous reflections. The radar sensor provides continuous level data to the PLC, which monitors the bulk storage tank and controls the scrubber process. Flowline is reliable level measurement. |

Sodium Hypochlorite Tank Radar Level Sensor_________________________________________________________________

When a global chemical distributor needed reliable level measurement of their terminal storage tanks, they turned to Flowline. The company supplies a wide range of liquid and solids products including pigments, oils, fuels, resins, solvents, polymers and surfactants. All of which, present differing application challenges such as vapor, corrosion, foam, coating, dust, dielectrics or varying angles of media repose. The operators wanted one level technology that can be applied with confidence across all such variables with minimal application engineering. For this reason, Flowline suggested the use of our radar level sensors, that provide reliable measurement in difficult applications, such as this highly vaporous and corrosive bleach tank. The radar sensor provides continuous level data to the PLC, which monitors the storage tank and alarms for replenishment. Flowline is reliable level measurement. |