|

|

|

Electronics production

|

|

In the electronics industry, increasing miniaturization and high production speeds are accompanied by highest quality standards. Sensors from Micro-Epsilon are used in high-tech production machines and production facilities and ensure that the high quality and requirements in terms of quality and efficiency are met. Thanks to the variety of models and the high precision of non-contact displacement sensors, Micro-Epsilon is a partner in almost all areas of the electronics industry - from chip production to complex assembly monitoring in the production of computers, smartphones and tablets. |

|

|

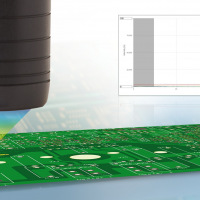

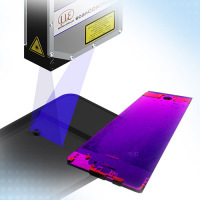

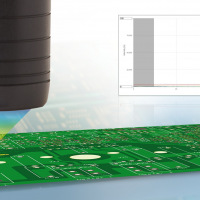

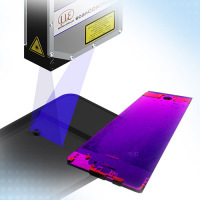

Thickness measurement of varnish on PCBs

|

|

In order to protect PCBs from environmental influences such as humidity, they are coated with a protective clear varnish. This ensures error-free operation. The automotive industry in particular demands a minimum thickness for this protective coating. Up to now, it was not possible to perform a measurement without destroying the target. Confocal sensors from Micro-Epsilon solve this measurement task without making contact with the target and therefore in a non-destructive manner. They provide the thickness values in real time. confocalDT IFS 2405 confocal sensors with a measuring range of 1 mm are used. These sensors are characterized by their extremely small measuring spot size of only 8 µm and excellent precision for measuring thin layers.

Controller with integrated light source for measuring rates up to 25kHz Controller with integrated light source for measuring rates up to 25kHz

Confocal chromatic sensors for displacement, distance, position, thickness Confocal chromatic sensors for displacement, distance, position, thickness

|

|

|

|

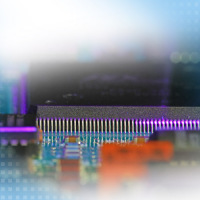

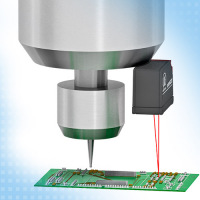

Measuring the height of pressed-in pins (Press-Fit Technology)

|

|

In addition to high accuracy with miniature dimensions, the production of electronic components also requires high speed processes that provide the highest quality. Therefore, many production steps in this area are highly automated. The company Automationpro has developed a machine that inspects the height of pressed-in contact pins on PCBs (Press Fit Technology) inline immediately after the pressing process. If the pins are not completely pressed through the openings, it is not possible to establish contact with other components, which may cause failure. Therefore, a scanCONTROL profile sensor scans each PCB in three dimensions. During this pressing process, the PCBs are fixed on a rotary table which moves the assembled module from the press-in position to the scanning position. The scanCONTROL is being moved by an actuator connected to an encoder which is being used for triggering the line scanner to ensure regular profile distances. Depending on the cycle time of the process, the component undergoes a complete scan within 7 seconds, generating 1,280 points per profile.

|

|

|

|

Assembly gap of display glass

|

|

|

|

|

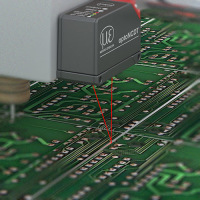

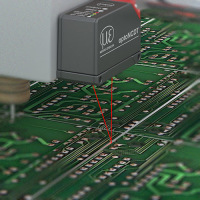

Measuring the coplanarity of IC pins

|

|

In SMT and reflow soldering processes, the coplanarity of the pins has to be inspected in order to assure a perfect soldering quality and to avoid failures. For this purpose, laser profile sensors from Micro-Epsilon are used. The scanner uses a blue laser diode which enables extremely high resolutions.

Laser scanners for 2D/3D profile measurements Laser scanners for 2D/3D profile measurements

|

|

|

|

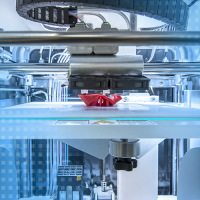

Print head positioning in laser transfer printers

|

|

With printing and exposure processes, the exact height of the print head or the distance from the object to be printed are crucial factors for the quality of the final product. Fast distance measurements with compact laser sensors from Micro-Epsilon enables fast readjustment and, in addition, edge detection.

Smart laser triangulation displacement sensor Smart laser triangulation displacement sensor

|

|

|

|

Dimensional inspection of fine mechanical structures

|

|

In assembly processes of smartphones and tablets, the dimensions and the assembly gap of the gasket are inspected in order to ensure high resistance to water and dust. Measurements are performed with Micro-Epsilon laser profile sensors that provide high resolution and profile frequency.

Laser scanners for 2D/3D profile measurements Laser scanners for 2D/3D profile measurements

|

|

|

|

Presence monitoring of electronic components

|

|

Laser triangulation sensors are used in fully automatic presence inspection of components on printed circuit boards. Very small details can be detected reliably due to the small light spot. The high measuring rate enables testing in the shortest cycle times.

Most Advanced Laser Displacement Sensor Most Advanced Laser Displacement Sensor

|

|

|

|

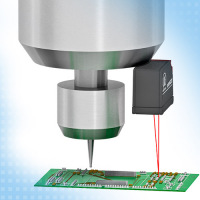

Distance measurement in dispensers for adhesives

|

|

In order to keep the adhesive dispenser always at the correct working distance, this distance value must be inspected continuously. For this purpose, compact laser sensors from Micro-Epsilon are used. Thanks to the fast measuring rate and the insensitivity to changing surface types, they continuously provide information about the distance of the glue dispenser.

Smart laser triangulation displacement sensor Smart laser triangulation displacement sensor

|

|

|

|

Color recognition in component sorting tasks

|

|

Particularly with automated mounting, components must be sorted according to their color. The colorSENSOR CFO is ideally suited for these high production speeds. Adjustable colors and tolerance enable high flexibility.

Compact True Color Sensor Compact True Color Sensor

|

|

|

|

Measuring scribe lines on PCB panels

|

|

Scribe lines are pressed into printed circuit boards for separation purposes. Laser sensors inspect the line depth which should be consistent in order to ensure reliable separation.

optoNCDT Laser Sensoren optoNCDT Laser Sensoren

|

|

|

|

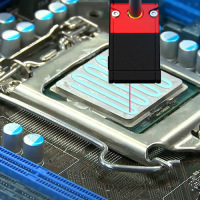

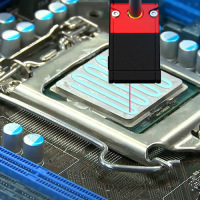

Heat conducting paste application

|

|

During the fully automatic application of heat conducting pastes, the correct dosage is a decisive factor. An overdosage of heat conducting paste impairs the thermal resistance, too little paste leads to thermal overload. The height of the paste bead is therefore detected using a laser triangulation sensor.

optoNCDT Laser Sensoren optoNCDT Laser Sensoren

|

|

|

|

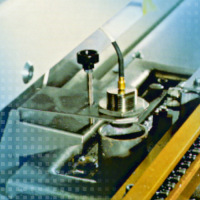

Measuring the solder-wave height on wave soldering machines

|

|

When soldering printed circuit boards in wave soldering systems, the height of the solder wave is an important criterion for the quality of the solder joints. The level of the soldering tin is detected directly above the solder wave using an eddyNCDT displacement sensor. The influence of the solder pot level and the pump contamination is thereby compensated for.

Inductive sensors (eddy current) for displacement, distance & position Inductive sensors (eddy current) for displacement, distance & position

|

|

|

|

|

|