|

||||||||

Stage load monitoring and limit alarm |

||||||||

|

||||||||

|

Advantages

|

||||||||

|

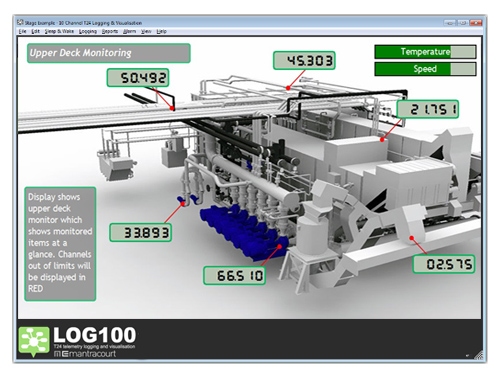

Software

Once the display channels are defined the user can quickly build graphical pages showing the data in a variety of formats including digital display or bars. Up to eight pages can be defined and the pages easily navigated between. A variety of image formats can be imported, including JPG, GIF, PDF and DXF.

T24LOG100 can log on demand, at pre-set intervals, on entering and leaving a pre-set overload and during an overload. It creates a CSV file which can be loaded for analysis into software programs such as Microsoft Excel. JSON format data is also available on demand via the built in web server.

|

||||||||

|

Key Features & Benefits

|

||||||||

|

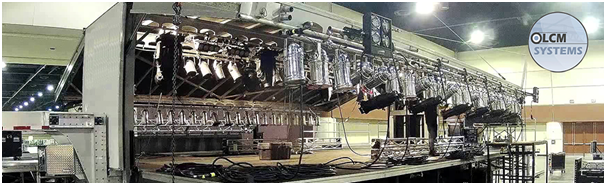

Solution for unpredictable load distribution

Safety for the performers and spectators are very important when considering the design of the truss set up. With tons of sound and lighting equipment hanging from the above, the need for even distribution of load is very important. The monitoring needs to have fast response due to the continuous movements of these audio visual (A/V) equipment.

There are situations whereby, due to the continuous movement of the A/V equipment, there would be uneven load distribution on one of the hoist and may reach its’ overload limit. Conditions may even worsen especially during outdoor set ups which are exposed to wind and snow build up on the roof. These conditions would greatly reduce the overload tolerance of the whole truss set up.

The solution is to identify the load distribution and ensuring safe installations during real-time performances. |

||||||||

|

||||||||

|

Mobility, Portability, User-Friendly

|

||||||||