|

|

Application 503

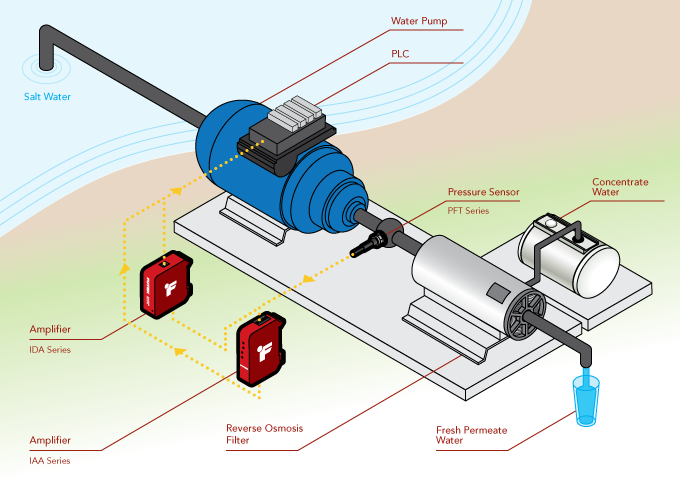

Desalination System Monitoring

Application Summary

Access to clean drinking water is a necessity for every individual around the world. In many drought-stricken areas, freshwater is limited while saltwater from the ocean is abundant and plentiful. Converting saltwater into freshwater is most commonly performed through high-pressure reverse osmosis. These systems require constant pressure delivered from a system of pumps to maintain membrane health and maximize system efficiency. By incorporating a pressure sensor into a control loop control system, the pump can maintain a constant operating pressure for maximum efficiency.

Products in Use

FUTEK's PFT510 Miniature Flush Mount Pressure Sensor paired with Instrumentation (IAA Series or IDA100 Amplifiers). |

|

|

How it Works

|