|

|

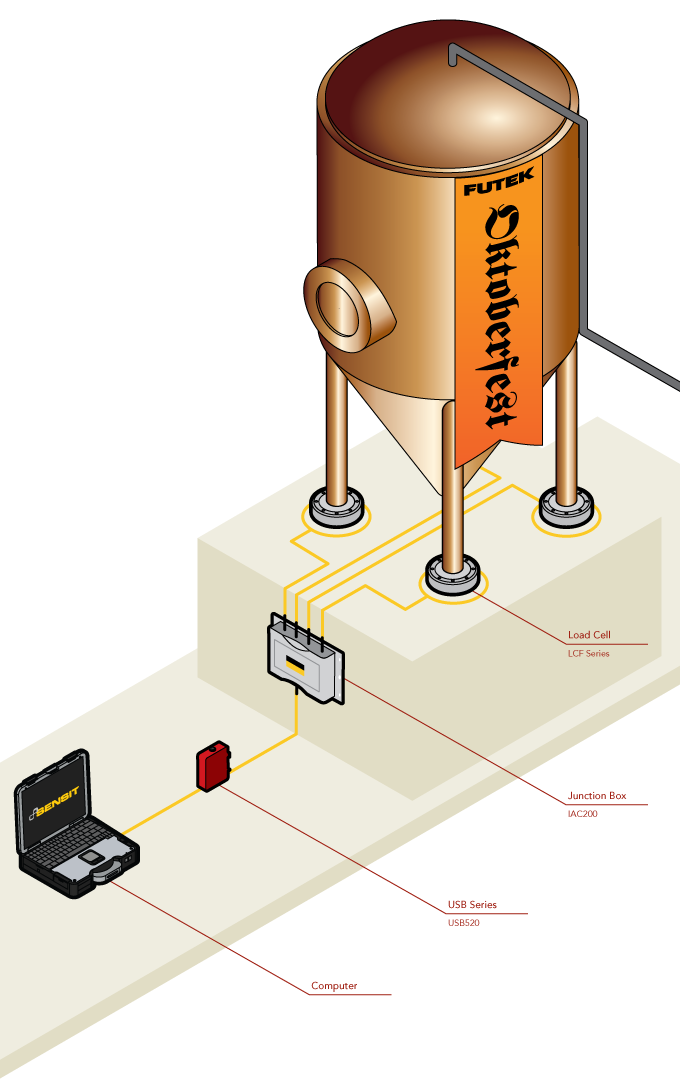

Application 153

Oktoberfest Fermentation Tank Measurement

Application Summary

Perfecting a good beer takes equal parts of great grains, as well as great equipment. Fermentation vessels are integral in the outcome of beer's taste, color, and alcohol content. Load cells are used to monitor the tank's contents throughout the brewing process.

Products in Use

Four Pancake Load Cells (LCF Family) paired with Instrumentation (IAC200 and USB520). |

|

|

How it Works

|