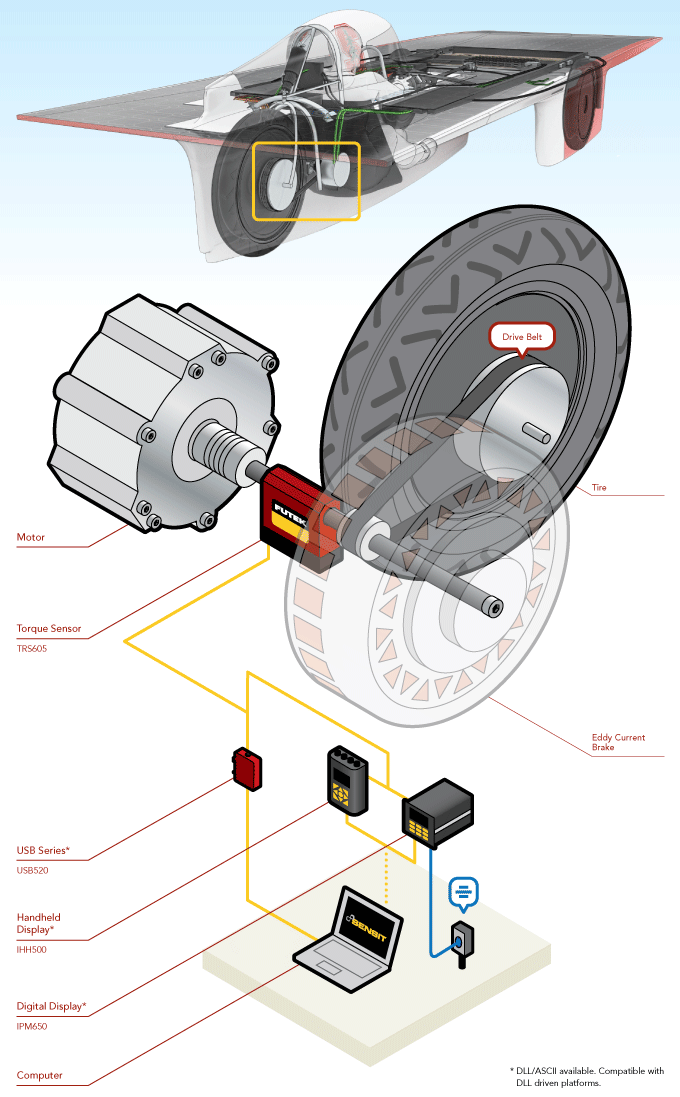

How it Works

- 1. The Stanford Solar Car Project team wanted to add a clever twist to their dynamometer (dyno): implement one of Xenith’s regenerative brakes as its energy absorber.

- 2. This setup would allow them to simultaneously study the efficiency of their regenerative braking system while testing their motor.

- 3. To gain perspective on if this approach could be realized, the SSCP Team called on the experts at FUTEK.

- 4. Consulting led to a clear direction that their dyno would need a TRS605 Rotary Torque Sensor at the center of its measurement system.

- 5. The TRS Series sensor integrates a rotary encoder with a freely spinning torque transducer.

- 6. The TRS605 could then be situated directly between the motor’s crankshaft and the regenerative brake allowing the both torque and displacement measurements to be simultaneously captured by a single sensor.

- 7. The USB520 is the ideal data exchange solution for systems that require translation of rotary torque encoder readings, such as angle and speed. Its compact and robust design also makes the USB520 fitting for this type of application.