How it Works

- 1. Wire bond testing systems enables two types of wire pull testing: destructive and non-destructive.

- 2. During a destructive wire pull test, a wire is pulled upward (perpendicular to the substrate) by a hook until there is either a bond failure or the wire breaks. This type of test is intended for process setup.

- 3. During a non-destructive wire pull test, a wire is pulled upward (perpendicular to the substrate) by a hook at a predesignated force to ensure high reliability packaging.

- 4. Wire bond testing systems also have the ability to perform the following test: Solder Ball Shear, Die Shear, Stud Bump Pull, Passivation Layer Shear, Ribbon Pull, Tweezer Peel, Fatigue and Push.

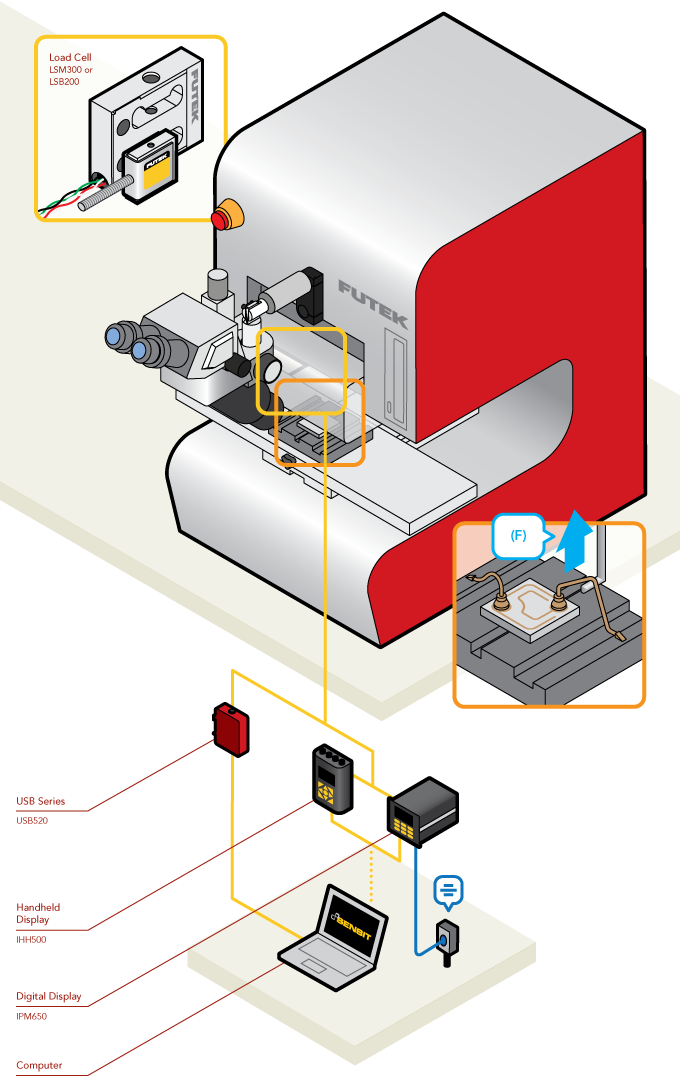

- 5. Specifically during a wire pull test FUTEK’s LSM300 precision load cell or LSB200 miniature load cell can be attached to the hook tool to measure the pulling force exerted on the wire under test.

- 6. These force measures can be streamed to a computer for analysis utilizing FUTEK’s USB Solutions.