Food Sanitization Soak Tank Guided Wave Radar Level Measurement______________________________________________________ When an Oregon food distributor needed reliable level measurement of their hose fitting sanitization tank, they turned to Flowline. The firm bulk delivers sugar and flour to their food manufacturing clients. Each night, the last truck driver to return, places the collective hose fittings in a soak tank, starts the sanitizer fill pump and goes home. There they had several overflows when the prior float level sensor would coat with particulates, stick and then fail to initiate pump shut off. The operator needed reliable level measurement, indication and automatic shut off. For this reason, Flowline suggested our guided wave sensor that’s unaffected by material build-up and our level controller. The guided wave sensor provides reliable level data to the controller which indicates the gallons and shuts off the fill pump. Flowline is reliable level measurement. |

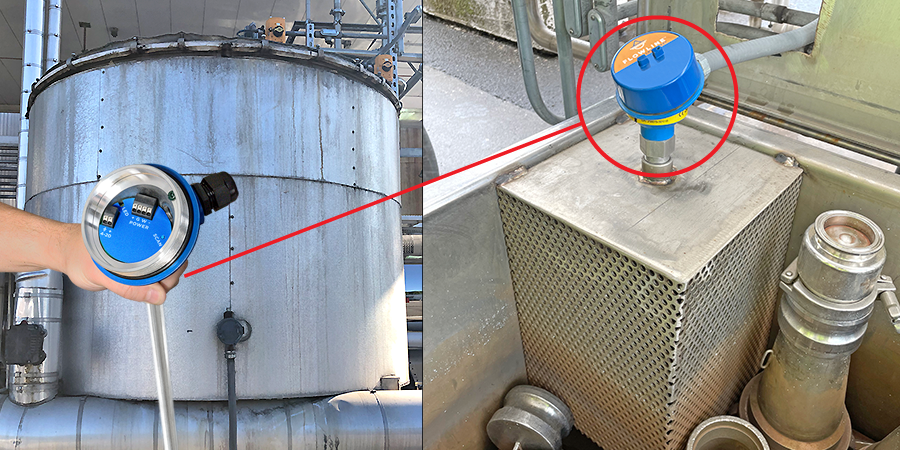

Oil Reclamation Bulk Tank Radar Level Transmitter______________________________________________________ When a Georgia oil reclamation company needed reliable level measurement of their storage tanks, they turned to Flowline. The firm transports used cooking oil from restaurants, stadiums, universities and commercial kitchens to their processing plant where they recycle oil. During recycling, the oil is heated, filtered and separated into grease, water and solids. The resulting grease is further heated, spun to remove any residual solids and pumped into storage tanks awaiting resale. There the plant operator said that previous ultrasonic level sensors became intermittent during and after pump transfer due to foam or temperature induced vapor, and they needed reliable level measurement. For these reasons, Flowline suggested our 80 GHz radar sensors that are unaffected by foam or vapor. The radar sensors provide reliable level data to the PLC which monitors the tanks and controls the fill process. Flowline is reliable level measurement. |

Foaming Wastewater Clarifier Tank Radar Level Transmitter______________________________________________________ When a Texas wastewater treatment plant needed reliable level measurement of their foaming clarifier tanks, they turned to Flowline. Ferric chloride is a highly effective flocculant that speeds the process of suspended solids separation during clarification. The downside of ferric chloride is its corrosive and increases the amount of foam in the process. The operator was dissatisfied with past pressure level sensors that first clogged and then corroded, and ultrasonic level sensors that became intermittent whenever foaming developed. For these reasons, Flowline suggested our non-contact 80 GHz radar sensors that are unaffected by foam or other such changes in the media, process or environment. The radar sensors provide reliable level data to the SCADA system, which controls the chemical feed and clarification process. Flowline is reliable level measurement. |

Water Treatment Lime Silo Radar Level Transmitter______________________________________________________ When a Virginia municipality needed reliable level measurement of their lime dosing silo, they turned to Flowline. With 10-14 grains per gallon, the local water supply is unusually hard. To combat this, the treatment plant doses calcium hydroxide into their clarifiers, which raises the pH and precipitates the ions that cause hardness. There the plant operator was dissatisfied with the prior bob mechanical level sensors that frequently clogged and eventually failed due to corrosion. As he said, “I need reliable, maintenance-free level measurement.” For these reasons, Flowline suggested our non-contact 80 GHz radar sensors with corrosion resistant PFA antennas, that are easy to configure and inspect via our LevelTap App with secure Bluetooth. The radar sensor provides reliable level data to the SCADA system that controls chemical feed and alarms for lime powder replenishment. Flowline is reliable level measurement. |

Diesel Generator Fuel Tank Ultrasonic Level Transmitter_________________________________________________________________ When a Mexico data center needed reliable level measurement of their backup diesel generator fuel tanks, they turned to Flowline. The communication hub processes thousands of client texts and emails per second and network downtime is not an option. But every year the country experiences significant hurricanes and earthquakes that can disrupt power for days or weeks. To address this, the center has installed four new gen-sets, each with a 2,000-liter diesel tank. The specifying engineer wanted to use non-contact ultrasonic level sensors, but was also concerned about humidity, condensation and their negative effects on ultrasonic measurement. For this reason, Flowline suggested our proprietary reflective ultrasonic level sensors that are not affected by condensation. The ultrasonic sensors provide reliable level data to the PLC, which monitors the tanks and alarms for refill. Flowline is reliable level measurement. |

Shipyard Wastewater Sump Radar Level Transmitter_________________________________________________________________ When a defense shipyard needed reliable level measurement of their wastewater lift stations, they turned to Flowline. The company services US navy frigate or coast guard ships providing maintenance and equipment upgrades. Their sumps receive all types of waste including diesel, paint, grease, oil, particulates, debris and corrosive saltwater. The operator said, “Pressure sensors corrode, float switches coat and ultrasonic sensors don’t perform when it foams up. Do you have anything that just works?” For these reasons, Flowline suggested our 80 GHz radar sensors that are unaffected by the media, easy to install and maintenance-free. The radar sensors provide reliable level data to the PLC, which monitors the sumps and controls the pump transfer to treatment. Flowline is reliable level measurement. |

Sewage Pump Lift Station Radar Level Transmitter_________________________________________________________________ When a Washington municipality needed reliable level measurement of a problematic sewer pump lift station, they turned to Flowline. The station is located in a huge sports park that’s filled with food trucks and hungry families on summer weekends. During which the sump receives dizzying sewage, illegal grease dumps, paper trash and food debris. The operator said that prior pressure level sensors failed due to clogging and ultrasonic level sensors became intermittent when foam or trash floated under their measurement beams. He said, “I need reliable, hassle-free measurement that just works.” For these reasons, Flowline suggested our 80 GHz radar sensors that are easy to install, unaffected by sump contents and maintenance-free. The radar sensors provide reliable level data to the SCADA, which monitors the level and controls the submersible pumps. Flowline is reliable level measurement. |

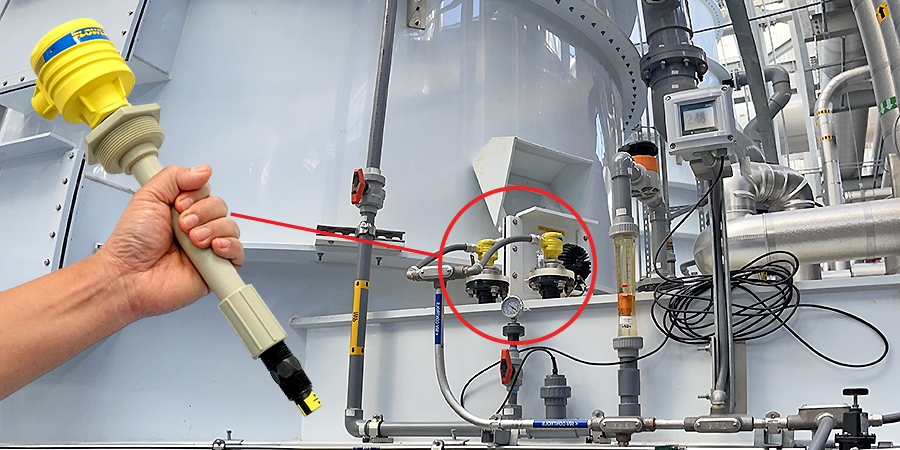

Reliable Scrubber Sump Wastewater Level Detection_________________________________________________________________ When a Gulf Coast semiconductor producer needed reliable level detection of their scrubber sumps, they turned to Flowline. Chemicals like silane, phosphine and arsine are used in wafer fabrication, and the resulting hazardous vapor stream must be scrubbed to EPA standards prior to release. The abatement process is constant during manufacturing and managing the scrubber sump levels is critical. The integrator needed a reliable, corrosion resistant level switch that’s unaffected by residual particulates or chemicals. For this reason, Flowline suggested our Switch-Pak single-point ultrasonic level switch that’s ruggedly constructed of corrosion resistant PP. Two ultrasonic switches provide reliable level detection to the PLC, which controls each sump. Flowline is reliable level measurement. |

SOFI Diesel Generator Tank Guided Wave Level Transmitter_________________________________________________________________ When SOFI Stadium needed reliable level measurement of their diesel generator tanks, they turned to Flowline. During a city power loss, three CAT generators immediately turn on, maintaining stadium and broadcast power for NFL games. At the front of each generator is a 58-gallon day tank pump system that automatically transfers fuel from the bulk storage tank to the generators. The pump control is level based and the stadium operators required absolute reliability, 12V battery operation and a rugged metal enclosure. For these reasons, Flowline suggested our guided wave level sensors that are ideal for diesel tank systems. The guided wave sensors provide reliable level data to the PLC, which monitors the day tanks and controls the transfer pumps. Flowline is reliable level measurement. |

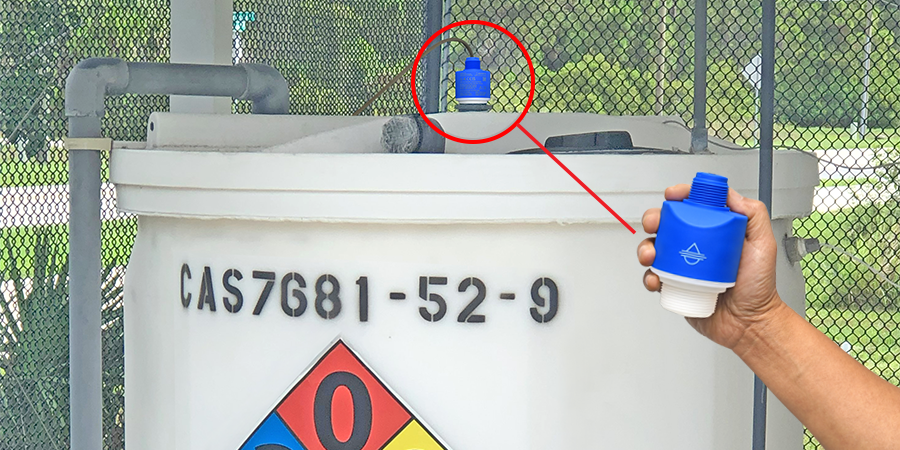

Sodium Hypochlorite Tank Radar Level Transmitter______________________________________________________ When a Florida county municipality needed reliable level measurement of their sodium hypochlorite storage tanks, they turned to Flowline. The water department uses NaCIO to boost residual chlorine in their drinking water distribution system, injecting it into 16” water pipelines. The operations manager said that previous ultrasonic level sensors became intermittent during the hot summer months due to vapor off-gassing, and they needed reliable level measurement. For this reason, Flowline suggested our 80-GHz radar sensors that are unaffected by chemical vapor or temperature extremes. The non-contact sensors are constructed entirely of PVDF and are ideal for corrosive applications. The radar sensors provide reliable level data to the SCADA, which controls the chemical feed and alarms for inventory replenishment. Flowline is reliable level measurement. |