LG10-0

Quick ViewView Full Details |

When a Texas equipment manufacturer needed reliable level measurement of their batch control systems, they turned to Flowline. Their dairy client required an automatic system to blend a critical disinfectant that’s used on cow utters. To makeup each batch, RO water, bleach and germicide are separately dispensed into a PVC tube. The level is measured and used to determine when the correct volume of each ingredient has been input. When done, the batch is transferred into an IBC and the cycle repeats until the tote is full. During blending, the solution foams and level accuracy is critical to batch quality. For this reason, Flowline suggested the use of our guided wave liquid level sensors that are highly accurate and unaffected by foam. The guided wave sensor provides continuous level data to the PLC, which in turn, monitors the tube and controls the batch process. Flowline is reliable level measurement. |

LG10/LG11

Quick ViewView Full Details |

When Metal Fuse of

Virginia needed reliable level measurement of their parts cleaning system, they

turned to Flowline. Trichloroethylene or TCE is a non-flammable industrial

solvent that’s commonly used in degreasing applications. The company needed to

measure the bath level of TCE as it recirculates through the wash conveyor with

a lot of spray and little space. For this reason, Flowline suggested the use of

our guided wave level sensors whose measurement is unaffected by spray. Each guided

wave level sensor provides continuous level data to the PLC, which in turn,

monitors the bath levels and actuates the recirculation pumps. Flowline is

reliable level measurement. |

LG10-0

Quick ViewView Full Details |

When the treatment

plant of Spring Township, PA needed reliable open channel flow measurement,

they turned to Flowline. As wastewater transfers through the plant, its passes

through several weir monitoring stations. The facility was using submersible

pressure sensors that suffered from two problems. First, during the extreme

winter cold, the sensors became erratic when the water temperature approached

freezing. Second, the sensors required ongoing maintenance as silt would clog

the diaphragm ports over time. For this reason, Flowline suggested the use of

our guided wave sensors that are temperature stable and unaffected by material

build up. The result is reliable open channel flow measurement. Here, an

EchoWave guided wave radar level transmitter is bracket mounted to an arm

suspended over the weir. The IP65 sensor was

easily set up using our WebCal configuration software. The 4-20 mA signal is

connected to the SCADA for flow measurement, control and alarms. Flowline is

reliable flow measurement. |

LG10-0

Quick ViewView Full Details |

When California’s Orange County Water District needed reliable level measurement of their precious reservoirs, they turned to Flowline. As water from the Colorado River transfers to the county, its retained and level monitored in their network of ponds. The municipality was using ultrasonic sensors that became erratic when the Santa Ana winds would blow floating vegetation against the pond bank, collecting under the sensor, and disrupting the acoustic signal return. For this reason, Flowline suggested the use of our coaxial guided wave sensors that house the antenna within a protective stainless pipe, separated from plant debris. The result is reliable water reservoir level measurement.

Here, an EchoWave

guided wave radar level transmitter is bracket mounted to a support structure

near the pond bank.

The IP65 sensor was

easily set up using our WebCal configuration software. The 4-20 mA signal is

connected to the SCADA for level measurement, control and alarms. Flowline is

reliable level measurement. |

LR31

Quick ViewView Full Details |

When Spartanburg Water in South Carolina needed reliable level measurement of their reservoir, they turned to Flowline. Fed by Lake Blalock, Hogback and Vaughn creeks, the Lake Bowen reservoir holds up to 6.3B gallons at full capacity, and reliable level measurement is critical to the water department and community they serve. The operators had experienced problems with their ultrasonic sensors during extreme wind events, and pressure sensors that would often clog in the muddy lake bottom. For this reason, Flowline suggested the use of our non-contact, pulse radar level sensors that are unaffected by environmental factors such as wind, and are available in general purpose or intrinsically safe versions. Mounted to the end of a platform, the IP68 radar sensor provides reliable level data to the SCADA, which in turn, monitors the level and controls the water flow into and out of the reservoir. Flowline is reliable level measurement |

LR15

Quick ViewView Full Details |

When a North Carolina manufacturer of hand cleansers and de-sanitizers needed reliable level measurement of their bulk storage tanks, they turned to Flowline. A critical ingredient is sodium laureth sulfate, a highly effective foaming agent that’s used in most of their products. But this is a challenging liquid to measure that’s sticky, very low dielectric and extremely foaming when agitated. For this reason, Flowline suggested the use of our pulse radar level sensors (that are unaffected by foam) installed in a metal stand-pipe to maximize the RF signal strength and reflectivity off the surface of the low dielectric media. The pulse radar level sensor provides continuous level data to the PLC, which in turn, monitors the tank levels and actuates low level alarms for chemical distributor replenishment. Flowline is reliable level measurement. |

LR30

Quick ViewView Full Details |

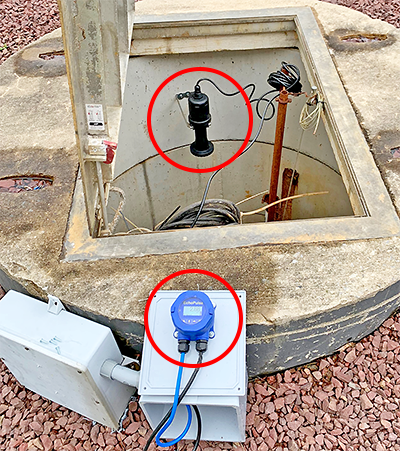

When a Southern

California municipality needed reliable level measurement in their sewer pump

lift stations, they turned to Flowline. Over the years, the operators had used

float level switches and ultrasonic level sensors in their lift stations with

limited success. The float switches required ongoing maintenance due to grease

build-up, and the ultrasonic sensors would go lost every time foam entered the

sump due to signal absorption. For this reason,

Flowline suggested the use of our pulse radar liquid level sensors that are

unaffected by wastewater variables such as grease or foam. The pulse radar

sensor provides continuous level data to the SCADA, which in turn, monitors the

sump level and controls the two submersible pumps. Flowline is reliable level

measurement. |

LR15

Quick ViewView Full Details |

When DairiConcepts of

Missouri needed reliable level measurement of their foaming waste sumps, they

turned to Flowline. A leading manufacturer of cheese, their wastewater streams

include thick foam and sticky particulates with the inclusion of steam and

chemicals during the cleaning process. Needless to say, their waste sump

applications are challenging and the company was dissatisfied with their

previous float and pressure level sensors that required weekly cleaning. For

this reason, Flowline suggested the use of our non-contact, pulse level radar

sensors that are unaffected by foam or steam. The pulse radar sensor

provides reliable level data to the PLC, which in turn, monitors the sump level

and controls the pump to transfer the content into wastewater treatment.

Flowline is reliable level measurement. |

LR15

Quick ViewView Full Details |

When

a Pacific Northwest marine aquarium and mammal rehabilitation center needed

reliable level measurement of their saltwater reservoir, they turned to

Flowline. Located on the coast, their exhibit and treatment pools are

replenished from an underground reservoir that’s frequently refilled with bay

water. During which, the high agitation generates surface foam that caused

their previous ultrasonic liquid level sensors to go lost due to signal

absorption. For this reason, Flowline suggested the use of our pulse radar

liquid level sensors that are unaffected by foam or agitation. The

pulse radar sensor provides reliable level data to the PLC, which in turn,

monitors the reservoir level and controls the transfer pumps. Flowline is

reliable level measurement. |

LR20

Quick ViewView Full Details |

When a Kansas chemical distributor needed reliable level measurement of their 600,000 gallon terminal storage tanks, they turned to Flowline. At the facility, sodium hydroxide and urea inventories are replenished from railcar deliveries. During the tank filing process, these highly corrosive liquids are agitated, which generates substantial foam and vapor. For this reason, Flowline suggested the use of our pulse radar level sensors that are corrosion resistant and unaffected by such variables. Each pulse radar sensor provides continuous level data to a controller, which in turn, displays the level and actuates a high level audible alarm (mounted on each sensor) to alert the operators when the tank is full. Flowline is reliable level measurement. |