Expert Logger

Quick ViewView Full Details |

Luminaire testing - Fully automated testing proceduresWe are daily surrounded by electro-technical illumination whether at work or at home. As for all electro-technical products, safety here is particularly important. For this reason, newly developed lamps must undergo a multitude of tests before being brought to market. Even the latest LED technology requires high-level testing for safety and reliability. Especially important here are thermal tests which are part of the EN 60598-1 standard to ensure that even in the event of malfunctioning, a lamp will not overheat and cause a fire. Delphin Technology offers the latest and fully automated measurement and evaluation technology. Application features

Typical areas of application

|

Expert Vibro

Quick ViewView Full Details |

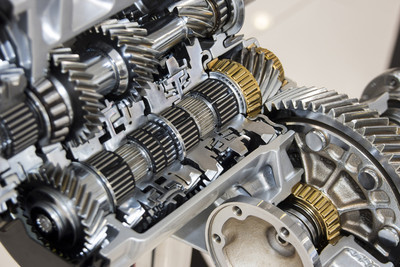

Gearbox test stand - Monitoring and alarm functionsGearbox is the main component in an automotive transmission system. The amount of vehicle noise is an important indicator on measuring the overall quality of vehicle, In order to locate the excessive noise caused by gearbox noise when a heavy vehicle is accelerating, the noise and vibration on the key parts of the gearbox were tested and analyzed. Transmission test stands of varying complexity and size are equipped with Delphin products for measurement and automation technology. Measurement procedures can then be implemented for specific requirements during product development and manufacture. A special feature is the single system’s ability to acquire vibration data at casings, bearings and shafts as well as to process data such as oil pressures, volume flows, bearing temperatures, torques and rotation speeds. Synchronous acquisition of all data is therefore guaranteed. A fully integrated system requiring no expensive interfaces is possible. The system is equipped with options for automation, analysis and evaluation which can be performed directly at the process using the Expert Vibro and ProfiMessage devices, and at a PC using the ProfiSignal software. Application features

Typical areas of application

|

Expert Logger

Quick ViewView Full Details |

Cleanroom Environment monitoring – Temperature & Humidity Continuous and manipulation-safe data acquisition and documentation is especially important in the pharmaceutical industry for production and storage requirements as well as for research and development. According to FDA Part 11, data acquisition and monitoring systems in cleanrooms must operate in compliance with GAMP/GMP guide-lines. Measurement data and limit values for parameters such as temperatures, humidity, particle count and pressures need to be acquired and monitored as well as archived in a manipulation safe format. Any user intervention relevant to the processes must also be recorded to an audit trail. Delphin Expert and Message series combined with the ProfiSignal software offers a complete system covering data acquisition through to monitoring, reporting and user management. Application features

Typical areas of application

|

Expert Logger

Quick ViewView Full Details |

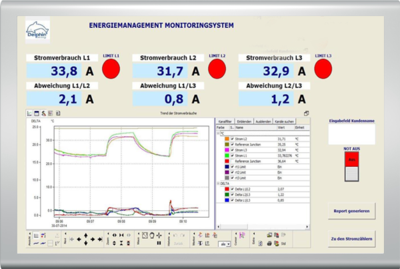

Energy Consumption Monitoring - EN50001 EN50001 standard requires high energy consuming industries to implement energy saving measures and, when required, energy management systems. Energy consumption data therefore requires recording which can be performed using Message devices. Due to their LAN interfaces, these can be located throughout a company and installed directly at the plant and machinery. Consumption data can then be transmitted to a central data server or workstation PC. Universal inputs can directly measure analog units such as pressures and flows. Pulse inputs and/or serial interfaces can acquire data from electric, gas and water meters. Characteristic values for consumption data are processed and monitored directly within the devices. All the information can be analyzed, portrayed and accounted for using the ProfiSignal software. Application features

Typical areas of application

|

Expert Logger

Quick ViewView Full Details |

Environmental simulation/climate chambers Climate chambers are the basis for long-term product testing that simulate actual operational conditions and the specific requirements of the application. Depending on the application, factors are combined such as temperature and humidity profiles, UV radiation and vibrations. Delphin Expert Logger continuously monitor and record test sample and climate data. An integrated data memory ensures the measurement data undergoes secure and continuous archiving. Faults and limit value violations can be reported via switch outputs, text messaging, fax or email. The ProfiSignal software portrays all the information in clear visualizations and diagrams and enables users to quickly access current and historical data. Application features

Typical areas of application

|

Expert Logger

Quick ViewView Full Details |

Sequential Event Recorder To analyze switching procedures, switching times and processes requires the acquisition of digital signals with high-level time resolution. Sampling rates in data loggers need to be much faster than typical PLC cycle times especially for fault analysis. An event recorder must also be capable of reliably processing relay and contact bouncing. Message and Expert devices are ideal for such tasks. Digital inputs record events at µsec resolution. Every input is recorded in parallel to enable precision determination of switch times. Depending on requirements, analog data can also be recorded in parallel. Internal logic and trigger channels enable events to be recorded and saved along with pre-and post-data. Application features

Typical areas of application

|

Expert Logger

Quick ViewView Full Details |

Portable Fault diagnostics tools The increasing rate of automation in modern plant and machinery requires high-resolution and detailed fault analysis for sporadically occurring errors. Delphin‘s mobile measurement case has proven itself in performing such tasks. By using the independently operating Expert and Message devices, no on-site PC or laptop support is required. Signals are attached through channel feeds on the case lid and connected to the analog and digital inputs using either plug-in or terminal connectors. Faults are recorded within the device to a ring memory, or as triggered data with pre and post event history. The data can then be accessed via networks, WLAN or USB and evaluated using ProfiSignal. Application features

Typical areas of application

|

ProfiMessage

Quick ViewView Full Details |

Standalone data acquisition and monitoring Processes must function smoothly. Process monitoring is essential for error-free products and to maintain the required standards of quality. Delphin‘s ProfiMessage and Expert devices are typically being used for process monitoring tasks and are ideal due to their combination of analog and digital inputs and the capability of acquiring process data also via PROFIBUS, ModBus and OPC. The devices can directly record and report limit value violations without having to rely on PC support. Limit value violations can also be portrayed in an alarm list. Data can be permanently and securely recorded to a ProfiSignal database. Application features

Typical application features

|

Expert Logger

Quick ViewView Full Details |

Portable Time-synchronized data acquisition Process data such as pressures, temperatures and flows often require synchronous recording with electrical data such as currents, voltages and power. An example here is fault analysis and energy data measurement in plant and machinery. For such measurement tasks, Delphin offers mobile case solutions. Electrical effective values as well as signal paths for AC and DC data can undergo recording and monitoring. Precision measurement transducers integrated within the case transmit electrical data via a RS485 interface to the data memories of Message devices. Evaluation takes place using ProfiSignal Go. The data memory can be read out within just a few mouse clicks and displayed in easy to read diagrams. Application features

Typical areas of application

|

Expert Logger

Quick ViewView Full Details |

Remote monitoring via UMTS/LTE Remote monitoring and data transmission is an important area for applications especially in machine and plant engineering. Message or Expert Transient devices are typically used in this sector due to their ability for independent data acquisition, recording, processing and monitoring. A UMTS module enables the devices to be accessed via a secure VPN tunnel making them independent of customer networks. The devices can be remotely configured, their data accessed, or automatically transmitted using a scheduler or FTP. If an alarm or failure occurs, the devices are capable of sending emails or text messages. The ProfiSignal software is network compatible to minimize configuration effort. Application features

Typical areas of application

|