LLB

Quick ViewDatasheetView Full Details |

Application: Batch Weighing Description: Known for their endurance testing capabilities, FUTEK's Load Button Series can be utilized in manufacturing batch weighing applications. |

LLB

Quick ViewDatasheetView Full Details |

Application: Bite Force Measurement Study Description: Miniature Load Buttons have been utilized in medical research studies by the University of Amsterdam to measure the bite strength of dementia patients. |

LLB

Quick ViewDatasheetView Full Details |

Application: Vampire Bite Force Description: In an attempt to estimate the strength of a vampire’s bite, Spike TV’s Deadliest Warrior called upon the assistance of a four-legged friend: an alligator. Utilizing FUTEK's LLB Miniature Load Button Load Cell, the esteemed group of experts for DW were able to confirm a bite force of nearly 1,800 lb. |

LLB

Quick ViewDatasheetView Full Details |

Application: Resistance Spot Welding Description: Resistance Spot Welding is a process in which pieces of metal are joined together by the heat created by the electrical resistance of the material combined with the forces applied by the electrode to hold the pieces together. The forces applied by the electrodes are very critical to the process, as the incorrect amount might cause cracks, holes, and failures in the welds. FUTEK’s LLB300 Miniature Load Button helps operators ensure that the welding machine is applying the correct amount of force. |

LLB

Quick ViewDatasheetView Full Details |

Application: Press Force verification Description: Load cells are frequently used with arbor presses as auditing tools to gauge the amount of force applied on a press fit or riveting process. |

LLB

Quick ViewDatasheetView Full Details |

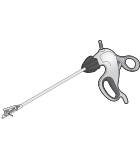

Application: Laparoscopic Tool Calibration Description: Minimally Invasive Surgery (MIS) and Single Port Access Surgery (SPAS) have dramatically reduced the risk and recovery time for patients for undergoing tumor extraction, heart valve and artery repair, and in-vitro fertilization. Whether performed with a robotic surgical system or with the trained hands of a surgeon, precision instrumentation is required to work with the delicate tissues of the patient while providing a precise, secure grip without exerting excess force. The forces applied with robotic instrumentation must be calibrated so that visual and haptic feedback mechanisms report the correct applied forces during surgery. Handheld instrumentation requires verification of the applied forces so the tactile sensations felt by the surgeon are predictable and consistent. Here we will demonstrate the verification and calibration of the jaws of a laparoscopic instrument. |

LLB

Quick ViewDatasheetView Full Details |

Application: Bag Sealer Validation Description: For sterilized and other sealed pouches and packaging, tears and partially broken seals are not always apparent. To mitigate seal failure and ensure seal integrity, verification of the heat sealing force is critical, as over/under applied sealing force can cause premature failure of the seal. This application utilizes a pair of LLB130 load buttons to monitor the force applied to pouch during the pouch sealing process. |

NASA/JPL

Quick ViewDatasheetView Full Details |

Application: MSL Mars Rover Cryogenic Multi-Axis Description: CFUTEK was commissioned by NASA to develop a cryogenic multi-axial sensor to operate within Curiosity's robotic arm. This sensor stands responsible to measure the torsion and force applied while the arm operates. |

QMA112

Quick ViewDatasheetView Full Details |

Application: Bottle Capping Torque Control Description: During cap application, ensuring consistent force and torque application is key to reducing product rejection rates. In systems that utilize child-proof caps, sanitized or sterilized packaging, verification of successful cap application is critical for seal validation and quality control. To accomplish this, a multi-axial sensor is used in the capping press to ensure precision, consistency, and seal integrity. |

MAU300

Quick ViewDatasheetView Full Details |

Application: Helicopter Cyclic Control Sensors Description: Flight controls require extreme auditing prior to in-flight use. FUTEK's MAU300 Gear Shift Load Cell provides quality assurance engineers with the appropriate tools to monitor the force applied to helicopter cyclic controls (joysticks). |