DL10

Quick ViewView Full Details |

Electroplating

is a process that uses electric current to reduce dissolved metal cations so

that they form a metal coating on an electrode or metal part. Hence, it changes

the surface properties of an object to improve its appearance, wear or corrosion

resistance. The basic electroplating process involves an alkaline cleaning,

acid pickling, electroplating and parts rinsing. During which, large quantities

of acidic wastewater are generated, laden with heavy metals. The wastewater

must be remediated and neutralized, prior to being released to the city sewer.

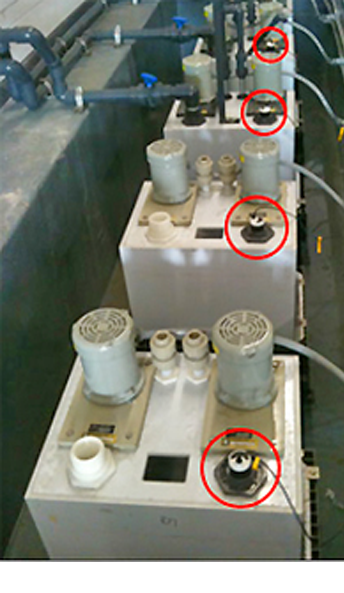

At this Midwest plating company, EchoPod ultrasonic level transmitters are

installed in each sump. The non-contact sensors provide continuous level data

to the PLC, which in turn, actuates the pumps to transfer the waste into

treatment. EchoPod is reliable plating lift station level measurement. |

DL24

Quick ViewView Full Details |

Cloud

data centers are the backbone of todays business, and fail-safe redundancy to

protect their clients data and service uptime is a fundamental premise of their

business model. Customers expect 24/7 service and business disruption is

unacceptable. As such, data centers deploy contingency plans, equipment and

security to address threats from natural disasters, fires, terrorism and power

outages. Battery backup systems and power generators are basic equipment at any

center. In the event of power loss, they protect data and ensure service uptime

for 24-72 hours depending upon their diesel fuel supply. Generators are

regularly exercised to confirm their good working order. At this financial data

center, EchoPod ultrasonic level transmitters are installed in each diesel

storage tank. The non-contact sensors provide continuous level data to the

building’s automation system. When the level drops to 80% of full capacity, the

tanks are refilled. EchoPod is reliable diesel generator level measurement. |

LU27

Quick ViewView Full Details |

Each

year, $9 trillion dollars of global trade, or about 85% of the world’s goods

are transported by ship across our oceans. Bulk carriers, cargo ships and oil

tankers are designed to transport enormous weight. Fully loaded, they have no

problem cutting through buffeting oceans and rocky seas. But, during cargo

on-load and off-load, the same ships are vulnerable to shifting loads and

imbalances that must be addressed by moving water ballast to maintain

stability. Ballast management is one of the many keys to safe seamanship, as

thousands of ballast gallons are typically moved while in port. Here, an

EchoSpan ultrasonic level transmitter is installed over each water ballast

tank. The non-contact sensor provides continuous level data to the ship’s PLC,

which in turn, automatically shifts ballast from one tank to another based upon

the angle of the ship. EchoSpan is reliable ship ballast level measurement. |

XP88-89

Quick ViewView Full Details |

The

global pharmaceutical industry develops about 3,000 new medicines a year,

addressing an array of health issues facing aging consumers. Given the extreme

pace of new product development, production facilities are constantly retooling

their manufacturing to meet the latest requirements. A relative constant is the

chemical storage, water treatment, chemical feed and wastewater treatment

equipment that supports their changing processes. At this US pharmaceutical

company, an EchoSafe explosion proof ultrasonic level transmitter is installed

on a sulfuric acid storage tank for inventory management. The non-contact

sensor is FM approved for use in hazardous locations, and provides continuous

level data to the PLC. EchoSafe is reliable hazardous level measurement. |

DL10

Quick ViewView Full Details |

The

Hotel and Motel Fire Safety Act of 1990 and National Fire Protection

Association NFPA standards require that all new multi-tenant buildings, 4

stories in height or more, must be fitted with fire sprinklers. The standards

also require high rise residential and commercial buildings to be outfit with

additional water storage capacity to ensure that sprinklers will have local

supply in the event that city water is cut off during the fire. Hence, water

storage tanks are now designed into high rises and architects attempt to

reclaim, treat and reuse available water where possible. At this New York

commercial high rise, rain water is captured on the roof, and periodically used

to refill the fire sprinkler storage tanks. Here, an EchoPod ultrasonic level

transmitter is installed over a collection. The non-contact sensor provides

continuous level data to the building’s automation system. EchoPod is reliable

fire sprinkler water level measurement. |

DL24

Quick ViewView Full Details |

About

50 billion chickens are consumed globally each year and the market is growing.

To meet the demand, processors are deploying new production methods and the

effectiveness and efficiency of their disinfection processes is a primary

concern. How do we prevent campylobacter, salmonella and listeria bacterial

contamination while killing, plucking, bleeding, eviscerating, cutting,

cleaning, packaging and shipping out more chickens this year? The proper

chemical treatment and washing techniques are critical to their success. This

US processor sprays trisodium phosphate (TSP), an alkaline compound, on

suspended chicken carcasses as they move down the production line. TSP

penetrates the chicken fat layers and disrupts the bacterial cells, killing

them on contact. Here, an EchoPod ultrasonic level transmitter is installed in

each TSP day tank. The non-contact sensor is connected to the PLC, which in

turn, automatically refills the day tank when low. EchoPod is reliable

disinfection level measurement. |

DL14

Quick ViewView Full Details |

US

metropolitan water districts deliver 850 million gallons of drinking water a

day. The water disinfection process often starts at the well pumping stations

where ground water is sourced, treated and pumped to the treatment plant. Given

the cost effectiveness of sodium hypochlorite versus ozone, chloramine and

ultraviolet, chlorine is the disinfectant of choice for many water districts.

Ultimately, those districts must decide whether they want to source chlorine

from a chemical distributor or generate it on-site. The decision making

criteria comes down to space, safety and capital expenditure. Suppliers can’t

deliver chemicals everyday, so bulk storage tanks are required, along with the

space to install and service them, and the higher liability associated with

offloading and storing large quantities of chlorine. Conversely, on-site

chlorine generators require 2-3 times the initial capital outlay, but they pay

for themselves within three years. At this pumping station, an EchoPod

ultrasonic level transmitter is measuring sodium hypochlorite that’s generated

and metered into the well water as its pulled from the ground. EchoPod is

reliable chlorine level measurement. |

LU27

Quick ViewView Full Details |

United

States data centers consume 575 gigawatts or 2% of all the power consumed off

the nations grid. Half of that energy is used to power computers and the other

half is used to cool the computers. Two types of cooling systems are deployed

including the newer rack cooling and older room cooling systems. Rack cooling

systems work by directly cooling a computer rack versus the entire room. In

this system, a wall of chilled water passes inches from the racks, neutralizing

the heat released from the back of the servers. Rack cooling is highly

efficient and cost effective. At this new US data center, chilled water

continuously circulates between two underground concrete bulk storage tanks and

the server room. An EchoSonic ultrasonic level transmitter is installed in each

storage tank. The non-contact sensors provide continuous level data to the PLC.

EchoSonic is reliable chilled water level measurement. |

DL14

Quick ViewView Full Details |

Global

printed circuit board (PCB) sales in 2015 were $58.6 billion and the average

PCB bill of materials represents 3.2% of every electronic device sold. PCB’s

mechanically support and electrically connect, electronic components using

conductive tracks etched from copper sheets and non-conductive epoxy substrate.

The most common etchants are ferric chloride, cupric chloride and hydrochloric

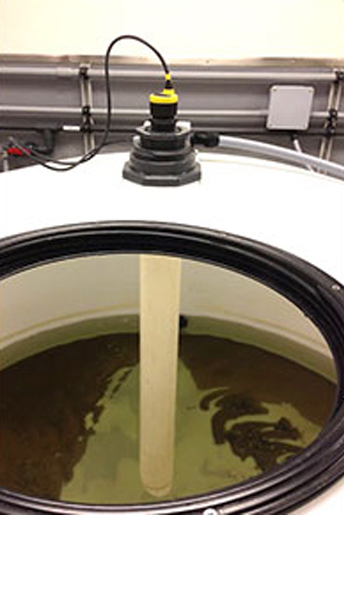

acid blended with cupric chloride. At this PCB manufacturer, four day tanks are

being monitored by EchoPod ultrasonic level transmitters. Hydrochloric acid is

pumped into the day tanks and mixed with anhydrous cupric chloride, creating an

acidic green solution. A standpipe has been installed to minimize the effects

of vapor and agitation on the sensor as the batch is blended. The non-contact

sensors deliver continuous level data to the PLC. EchoPod is reliable PCB

etchant level measurement. |

LU20

Quick ViewView Full Details |

Crude

oil is an essential commodity used in the refinement of gasoline. The majority

of gasoline is derived from petroleum naphtha, an intermediate hydrocarbon

liquid. Petroleum naphtha has low octane ratings that must be desulfurized and

then catalytically reformed to produce high-octane gasoline. To do so,

petroleum naphthas are typically broken down using toluene, an aromatic

hydrocarbon that is widely used as industrial feedstock or solvent which is

capable of dissolving paints, thinners and sealants. In gasoline, toluene

dissolves the sulfur, thus raising the octane to appropriate levels for use in

combustible engines. In this chemical plant, toluene is produced and contained

in a bulk tank for later use in petroleum refining processes. Toluene is a

highly volatile liquid that requires instruments with hazardous certification.

The intrinsically safe EchoTouch ultrasonic level transmitter was chosen for

this application, and combined with an intrinsically safe DataLoop level

indicator for hazardous level measurement and indication. |